Taiwan's small factory dominates global specifications, allowing Mini LED to counterattack OLED

- author:

- 2022-11-24 09:30:48

Taiwan's soft power in manufacturing has been stimulated in this wave of global supply chain restructuring. A small factory with a share capital of less than 400 million yuan and a factory located in Kaohsiung's Nanzi Industrial Park has developed products that may rewrite the global standard specifications of Mini LED lead frames, and even allowed the original panel factory to find a way to compete with organic light emitting diodes (oled). A weapon.

This company is Changhua Technology, which was chased by chip factories for semiconductor lead frames two years ago. Under the efforts of the R & D team for more than two years, it was unexpectedly discovered that the unique method of the lead frame can be used to improve the brightness and reduce the cost through etching process and epoxy resin transfer molding technology, becoming a vehicle cockpit display (instrument panel, center console, rear seat entertainment display system) and the new darling of notebooks and televisions. The company is also preparing to apply for PMMS airtightness inspection specifications to be included in the JEDEC standard. Chairman Huang Jianeng excitedly said that Changke has The ability to dominate global standard specifications.

Six years ago, Changke purchased the lead frame business of Nisho Sumitomo Metal Mining Group, and became the target of various chip factories competing for production during the global chip shortage two years ago. More than six years later, Changke took advantage of the unique working method of Japanese businessmen in lead frames and accidentally discovered that it was possible to use the other party's etching process and the epoxy resin transfer molding technology accumulated by Changke for many years to open the LED chip's light emitting angle (referred to as the light angle) through the planar metal lead frame, which is better than the traditional packaging structure's 130 degrees. This allows the Mini LED backlight with originally limited die layout to find a solution that significantly reduces costs and significantly improves contrast brightness.

With higher brightness and contrast, it is particularly important for the cockpit displays (instrument panels, center consoles, rear seat entertainment display systems) that are currently rapidly introduced into vehicles. This makes the display easier to read in a variety of lighting conditions, breaking through reading limitations in daylight or at night.

In addition, Mini LED backlights can better control light scattering and use energy more efficiently than traditional backlights. When used in car displays, it can extend the service life of vehicle batteries; when used in TVs, it has a wider color gamut than OLED. Especially for TVs with large size over 75 inches, the cost is lower than OLED.

The flat metal lead frame Huang Jianeng talks about is actually almost the same product as the ICs currently used in various semiconductor components such as mobile phones, microcontrollers, discrete components, diodes and power management chips. However, under the development of the company's R & D team, it can also be used as a lead frame for Mini LED chips. Moreover, through the exclusive development of a set of thermosetting plastic (EMC), injecting a thin metal lead frame that is etched to leave the place where the Mini LED chips are placed. A flat-plate LED carrier board is formed and then handed over to the LED packaging factory. Through die cutting, die fixing, sealing, and monomer cutting procedures, the Mini LED dies are sealed in the metal lead frame.

Changke named the Mini LED EMC Flat Metal Lead Frame (PMMS). Osram, a German company that has received long-term cooperation, has introduced Mini LED panels for automotive use, and developed automotive instrument panels and central control systems for first-tier German car manufacturers. In addition, first-tier car manufacturers in the United States also learned that the Mini LED lead frame developed by Changke can allow the LED chips in the display screen to achieve high heat dissipation, high reflectivity, high temperature resistance and high air tightness. They also use the supply system to find Changke.

Huang Jianeng pointed out that although the Mini LED backlight is less thin than OLED in mobile phones, it is very competitive in cars, notebooks, desktop displays and TVs, especially in TVs. In the future, it will definitely make Mini LED TVs have better contrast and brightness than OLED, and are cheaper.

TAG:

Guess you want to see it

Popular information

-

Why has small-pitch LED displays become the first choice for terminal displays in the security marke

-

Lianjian Optoelectronics brings its first display solution to a shocking appearance at ISE 2023 exhi

-

How Zhaochi Jingxian promotes the development of the LED industry through COB technology

-

Financing boom in Mini/Micro LED sector: Capital competition lights up a new track for technology

-

Micro-LED: The dawn and challenges of a new era of commercialization

-

The policy is blowing vigorously, and the domestic demand market in the LED display industry is stro

-

ISE 2023| Participating in 18 consecutive exhibitions, Alto Electronics has embarked on a new journe

-

2023 The performing arts market is off to a good start. Can rental screens remain popular?

-

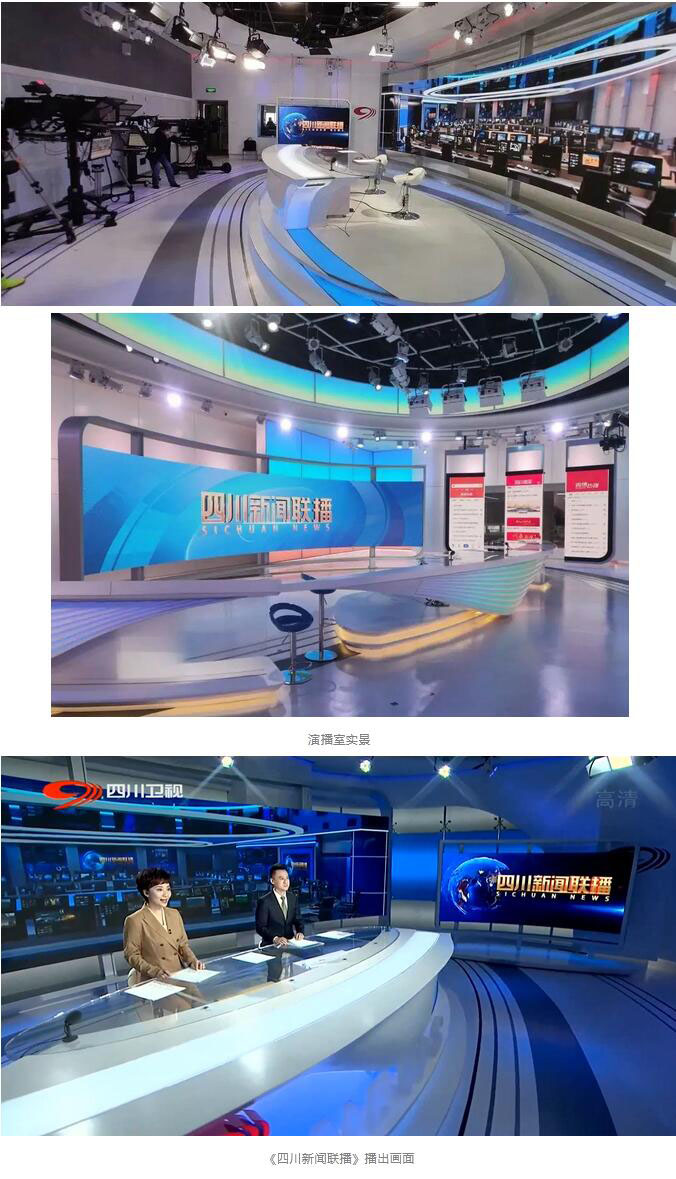

Abbison's big screen shines in the Sichuan Radio and Television News Studio

-

315 consumer rights day| Liard has won multiple honorary certifications from China Quality Inspectio

the charts

- Taiwan's small factory dominates global specifications, allowing Mini LED to counterattack OLED

- Abbison's big screen shines in the Sichuan Radio and Television News Studio

- Inventory of top ten keywords in the large-screen commercial display industry in 2022

- When the exhibition is in progress| Go directly to ISE! Watch the live tidbits first

- to shine| Shendecai shines at ISE 2023

- BOE MLED presents its excellent technical products at ISE exhibition in Spain

- Lianjian Optoelectronics brings its first display solution to a shocking appearance at ISE 2023 exhi

- ISE 2023| Participating in 18 consecutive exhibitions, Alto Electronics has embarked on a new journe

- Display companies go to sea collectively in the New Year, and 14 companies appear at ISE 2023

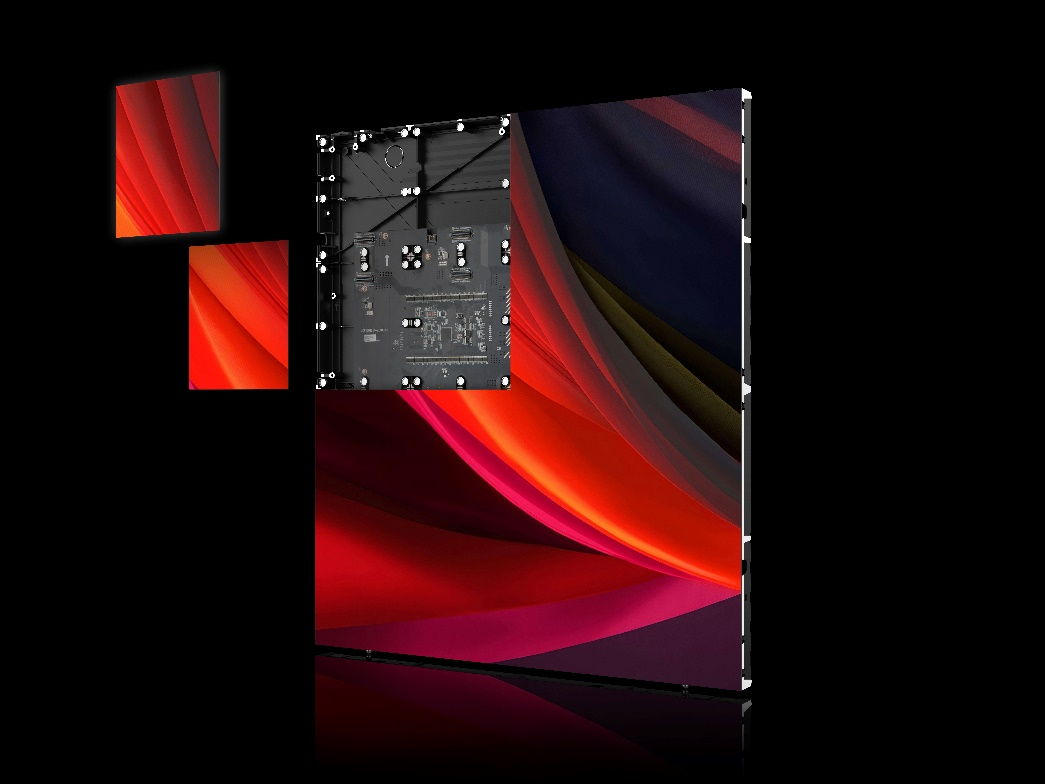

- Jingtai debuted at the 2023 ISE exhibition, empowering new scenarios with leading LED solutions