Many companies have intensively publicized Micro LED patents to lead the industry's technological in

- author:

- 2025-04-07 13:40:26

Recently, important companies in the industries such as Zhaochi Semiconductor, Gaoke Huaye, and Gaoke Video have announced Micro LED-related patents. The MiP, chips, epitaxial wafers and other technologies they cover have attracted widespread attention in the field of Micro LED.

Zhaochi Semiconductor has made remarkable achievements in the research and development of Micro LED technology. Recently, three Micro LED patents have successfully entered the effective authorization stage. These patents mainly focus on the fields of Micro LED epitaxial wafers and chip manufacturing.

兆驰半导体在 Micro LED 技术研发方面成果斐然,近期有三项 Micro LED 专利成功进入有效授权阶段,这些专利主要聚焦于 Micro LED 外延片以及芯片制造领域。

On April 1, a patent titled microled epitaxial wafer and its preparation method, and MicroLED chip entered the effective authorization stage.

4 月 1 日,一项名为 "MicroLED 外延片及其制备方法、MicroLED 芯片" 的专利进入有效授权阶段。The invention belongs to the field of optoelectronic technology, and the disclosed Micro LED epitaxial wafer has a unique structure. It comprises a substrate on which a buffer layer, an N-type GaN layer, a multi-quantum well layer, and a P-type GaN layer are sequentially arranged. Wherein, the first multiple quantum well layer consists of at least one set of a first InGaN quantum well layer, a first AlGaN/GaN superlattice layer and a first GaN quantum barrier layer stacked in sequence; the second multiple quantum well layer consists of at least one set of a second InGaN quantum well layer, a second AlGaN/GaN superlattice layer and a second GaN quantum barrier layer stacked in sequence; and the third multiple quantum well layer consists of at least one set of a third InGaN quantum well layer, a hole injection layer and a third GaN quantum barrier layer stacked in sequence. With this design, this Micro LED epitaxial wafer can significantly improve the light efficiency of Micro LED chips under low operating current densities, providing strong technical support for related products in energy-saving and efficient operation.

As early as March 18, the two patents of Micro-LED epitaxial wafer and its preparation method, Micro-LED and high-efficiency Micro-LED epitaxial wafer and its preparation method, and Micro-LED have entered the effective authorization stage. The common feature is that they can improve luminous efficiency.

早在 3 月 18 日,"Micro - LED 外延片及其制备方法、Micro - LED" 以及 "高光效 Micro - LED 外延片及其制备方法、Micro - LED" 这两项专利就已进入有效授权阶段,它们的共同特点是均可提升发光效率。

其中,"Micro - LED 外延片及其制备方法、Micro - LED" 专利下的 Micro‑LED 外延片结构依次为衬底、N 型 GaN 层、第一多量子阱层和 P 型 GaN 层,第一多量子阱层由交替层叠的量子阱层和第一量子垒层组成。The quantum well layer specifically includes a first GaN layer, a first InGaN layer, an InxGa1-xN layer and an AlN layer stacked in this order; the first quantum barrier layer consists of a first AlGaN layer, an N-type AlGa1-N layer, an undoped AlaGa1-aN layer, an N-type AlGa1-N layer and a second GaN layer stacked in this order. In this structure, the proportion of In composition in the first InGaN layer changes gradually and has a maximum value x; the proportion of Al composition in the first AlGaN layer changes gradually and has a minimum value.

而 "高光效 Micro - LED 外延片及其制备方法、Micro - LED" 专利中的 Micro‑LED 外延片结构依次为衬底、缓冲层、非掺杂 GaN 层、N 型 GaN 层、多量子阱层、空穴扩展层、空穴存储层和空穴层。The hole expansion layer has a periodic structure, and each cycle includes a BN layer and a lightly Mg-doped GaN layer stacked in sequence; the hole storage layer is also a periodic structure, and a GaN layer, an InGaN layer and an Mg-doped AlGaN layer are stacked in sequence each cycle; The hole layer is also a periodic structure, with a P-type BInGaN layer, an Mg3N2 layer and a P-type GaN layer stacked in sequence each cycle, and the doping concentration of the P-type GaN layer is 11019 cm-3. These carefully designed structures provide an innovative path for improving the luminous efficiency of Micro-LEDs.

On March 28, a patent filed by Shanxi Gaoke Huaye Electronics Group Co., Ltd. on a preparation method for quantum dot Micro MIP devices entered the authorization stage.

3 月 28 日,山西高科华烨电子集团有限公司一项关于 "一种量子点 Micro MIP 器件制备方法" 的专利进入授权阶段。This patent belongs to the field of semiconductor display technology, and its preparation method includes multiple key steps:

该发明将蓝光 Micro COW 与量子点材料相结合,成功实现色彩转换,可生成红光与绿光,大幅提高了显示器件的色彩饱和度与细腻度,显著提升整体显示画质。At the same time, the application of massive transfer technology and laser lift-off technology makes the chip transfer and packaging process more efficient and accurate, effectively reduces losses in the manufacturing process, and helps control manufacturing costs. In addition, optimized device cutting and packaging processes ensure device performance and quality while also improving production efficiency.

On March 11, Shanxi High-Tech Video Technology Co., Ltd.'s invention patent for the preparation method of a monolithically integrated common cathode full-color MicroLED device entered the substantive review stage.

3 月 11 日,山西高科视像科技有限公司的 "一种单片集成共阴全彩 MicroLED 器件的制备方法" 发明专利进入实质审查阶段。The invention belongs to the technical field of Micro LED displays, and its unique preparation process is as follows: first, spraying graphene quantum dots on the surface of a Micro LED light-emitting device to form a quantum dot coating; then, evenly dividing the quantum dot coating into a red graphene quantum dot coating area, a green graphene quantum dot coating area, and a blue graphene quantum dot coating area; Subsequently, the red graphene quantum dot coating area is first brought into contact with the N element dopant, and then the green graphene quantum dot coating area to be doped is brought into contact with the N element dopant, while the blue graphene quantum dot coating area is not brought into contact with the N element dopant. Through such a process, the invention can use a quantum dot coating to realize the conversion of red, green and blue colors. This effectively reduces the difficulty of the RGB full-color process, avoids the problem of high-cost repair, and improves the display. Uniformity provides an innovative solution for the preparation of full-color Micro LED devices.

随着兆驰半导体、高科华烨、高科视像等企业在 Micro LED 专利技术上的不断突破与公示,有望引领 Micro LED

Zhaochi Semiconductor has made remarkable achievements in the research and development of Micro LED technology. Recently, three Micro LED patents have successfully entered the effective authorization stage. These patents mainly focus on the fields of Micro LED epitaxial wafers and chip manufacturing.

兆驰半导体在 Micro LED 技术研发方面成果斐然,近期有三项 Micro LED 专利成功进入有效授权阶段,这些专利主要聚焦于 Micro LED 外延片以及芯片制造领域。

On April 1, a patent titled microled epitaxial wafer and its preparation method, and MicroLED chip entered the effective authorization stage.

4 月 1 日,一项名为 "MicroLED 外延片及其制备方法、MicroLED 芯片" 的专利进入有效授权阶段。The invention belongs to the field of optoelectronic technology, and the disclosed Micro LED epitaxial wafer has a unique structure. It comprises a substrate on which a buffer layer, an N-type GaN layer, a multi-quantum well layer, and a P-type GaN layer are sequentially arranged. Wherein, the first multiple quantum well layer consists of at least one set of a first InGaN quantum well layer, a first AlGaN/GaN superlattice layer and a first GaN quantum barrier layer stacked in sequence; the second multiple quantum well layer consists of at least one set of a second InGaN quantum well layer, a second AlGaN/GaN superlattice layer and a second GaN quantum barrier layer stacked in sequence; and the third multiple quantum well layer consists of at least one set of a third InGaN quantum well layer, a hole injection layer and a third GaN quantum barrier layer stacked in sequence. With this design, this Micro LED epitaxial wafer can significantly improve the light efficiency of Micro LED chips under low operating current densities, providing strong technical support for related products in energy-saving and efficient operation.

As early as March 18, the two patents of Micro-LED epitaxial wafer and its preparation method, Micro-LED and high-efficiency Micro-LED epitaxial wafer and its preparation method, and Micro-LED have entered the effective authorization stage. The common feature is that they can improve luminous efficiency.

早在 3 月 18 日,"Micro - LED 外延片及其制备方法、Micro - LED" 以及 "高光效 Micro - LED 外延片及其制备方法、Micro - LED" 这两项专利就已进入有效授权阶段,它们的共同特点是均可提升发光效率。

其中,"Micro - LED 外延片及其制备方法、Micro - LED" 专利下的 Micro‑LED 外延片结构依次为衬底、N 型 GaN 层、第一多量子阱层和 P 型 GaN 层,第一多量子阱层由交替层叠的量子阱层和第一量子垒层组成。The quantum well layer specifically includes a first GaN layer, a first InGaN layer, an InxGa1-xN layer and an AlN layer stacked in this order; the first quantum barrier layer consists of a first AlGaN layer, an N-type AlGa1-N layer, an undoped AlaGa1-aN layer, an N-type AlGa1-N layer and a second GaN layer stacked in this order. In this structure, the proportion of In composition in the first InGaN layer changes gradually and has a maximum value x; the proportion of Al composition in the first AlGaN layer changes gradually and has a minimum value.

而 "高光效 Micro - LED 外延片及其制备方法、Micro - LED" 专利中的 Micro‑LED 外延片结构依次为衬底、缓冲层、非掺杂 GaN 层、N 型 GaN 层、多量子阱层、空穴扩展层、空穴存储层和空穴层。The hole expansion layer has a periodic structure, and each cycle includes a BN layer and a lightly Mg-doped GaN layer stacked in sequence; the hole storage layer is also a periodic structure, and a GaN layer, an InGaN layer and an Mg-doped AlGaN layer are stacked in sequence each cycle; The hole layer is also a periodic structure, with a P-type BInGaN layer, an Mg3N2 layer and a P-type GaN layer stacked in sequence each cycle, and the doping concentration of the P-type GaN layer is 11019 cm-3. These carefully designed structures provide an innovative path for improving the luminous efficiency of Micro-LEDs.

On March 28, a patent filed by Shanxi Gaoke Huaye Electronics Group Co., Ltd. on a preparation method for quantum dot Micro MIP devices entered the authorization stage.

3 月 28 日,山西高科华烨电子集团有限公司一项关于 "一种量子点 Micro MIP 器件制备方法" 的专利进入授权阶段。This patent belongs to the field of semiconductor display technology, and its preparation method includes multiple key steps:

- S1. Prepare raw materials: Lay the foundation for the subsequent preparation process and ensure accurate selection of materials.

- S2. Sapphire coating: Special coating treatment is carried out on sapphire to prepare for subsequent processes.

- S3. Mass transfer: Use advanced mass transfer technology to efficiently realize chip transfer.

- S4. Quantum dot slot: Build a quantum dot slot to provide suitable space for the placement of quantum dots.

- S5. Quantum dot spraying: Accurately spray the quantum dots to the corresponding positions.

- S6, quantum dot packaging: quantum dots are encapsulated to ensure stable performance.

- S7. Laser lift-off: Use laser lift-off technology to accurately handle the chip packaging process.

- S8, RDL packaging: Carry out RDL packaging to further improve the device packaging process.

- S9. Device cutting: Cut the device to meet the application size requirements.

- S10. Device sub-test: Conduct sub-test on the prepared devices to ensure product quality.

该发明将蓝光 Micro COW 与量子点材料相结合,成功实现色彩转换,可生成红光与绿光,大幅提高了显示器件的色彩饱和度与细腻度,显著提升整体显示画质。At the same time, the application of massive transfer technology and laser lift-off technology makes the chip transfer and packaging process more efficient and accurate, effectively reduces losses in the manufacturing process, and helps control manufacturing costs. In addition, optimized device cutting and packaging processes ensure device performance and quality while also improving production efficiency.

On March 11, Shanxi High-Tech Video Technology Co., Ltd.'s invention patent for the preparation method of a monolithically integrated common cathode full-color MicroLED device entered the substantive review stage.

3 月 11 日,山西高科视像科技有限公司的 "一种单片集成共阴全彩 MicroLED 器件的制备方法" 发明专利进入实质审查阶段。The invention belongs to the technical field of Micro LED displays, and its unique preparation process is as follows: first, spraying graphene quantum dots on the surface of a Micro LED light-emitting device to form a quantum dot coating; then, evenly dividing the quantum dot coating into a red graphene quantum dot coating area, a green graphene quantum dot coating area, and a blue graphene quantum dot coating area; Subsequently, the red graphene quantum dot coating area is first brought into contact with the N element dopant, and then the green graphene quantum dot coating area to be doped is brought into contact with the N element dopant, while the blue graphene quantum dot coating area is not brought into contact with the N element dopant. Through such a process, the invention can use a quantum dot coating to realize the conversion of red, green and blue colors. This effectively reduces the difficulty of the RGB full-color process, avoids the problem of high-cost repair, and improves the display. Uniformity provides an innovative solution for the preparation of full-color Micro LED devices.

随着兆驰半导体、高科华烨、高科视像等企业在 Micro LED 专利技术上的不断突破与公示,有望引领 Micro LED

TAG:

Guess you want to see it

Popular information

-

CEO of TV IKLAN Group, Indonesia's largest media company, led a delegation to inspect MNLED and the

-

Zhouming Technology lights up Saudi Dammam landmarks and reshapes the city's new business card of li

-

Ming Xincheng, a subsidiary of Hongli Zhihui: Use light as a pen to paint the colorful night view of

-

Xinyasheng, a frequent visitor to international events, is making another effort! 1142㎡ transparent

-

Alto Electronics 'LED technology empowers China B League: ignites enthusiasm for urban football and

-

BOE's PH2 equipment was moved in advance, and the MLED direct display business entered a new stage

-

Liard·Virtual Moving Points Appears at the Beijing Film Festival: Spatial computing technology build

-

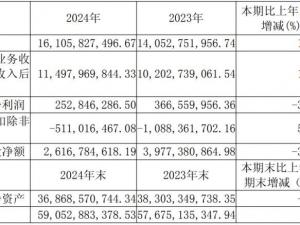

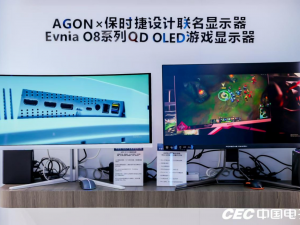

Digital empowerment and development of new productivity! TPV Technology Group debuted at the 7th Dig

-

Warm congratulations on MNLED's successful application for the U.S. trademark!

-

Zhaochi Semiconductor Mid-Year Summary Meeting: Taking woes as a mirror and moving towards innovatio

the charts

- CEO of TV IKLAN Group, Indonesia's largest media company, led a delegation to inspect MNLED and the

- Innolux joins hands with Yuantai, TPV and others to introduce large size color electronic paper into

- Xida Electronics signs a strategic cooperation agreement with Changbai Mountain Chixi District Manag

- Liard joins hands with "Three-Body" to open a new era of science fiction drama in China

- Zhaochi Semiconductor joins hands with Li Xing Semiconductor. Want to do big things?

- Zhou Ming joins hands with the Guangdong Basketball Association to produce another masterpiece! The

- ISE2023 Abbison's first exhibition in the new year has received frequent good news, and the immersiv

- Samsung Display and APS "work together" to create 3500ppi Micro OLED

- Zhouming Technology and Perfect World officially reached an educational ecological partnership!

- Longli Technology:Mini-LED has been shipped in batches to some in-vehicle customers, VR customers, e