Six companies including Zhaochi and Qianzhao announced new Micro LED patents

- author:

- 2025-05-13 14:49:38

At a time when Micro LED display technology is accelerating breakthroughs, many domestic core companies in the display field continue to increase their technology research and development, using patent innovation as a breakthrough to promote industrial upgrading. Recently, companies such as Zhaochi Semiconductor, Dry Light Optoelectronics, and Xinying Optoelectronics have intensively disclosed patent results related to Micro LEDs. Their technologies cover core aspects such as epitaxial wafer manufacturing, chip structure optimization, and packaging process innovation, aiming to improve light efficiency and power performance, and simplify production processes and accelerate the commercialization process.

Zhaochi Semiconductor: Innovative packaging structure achieves single-core full-color display

On May 6, Zhaochi Semiconductor disclosed" patents on Micro LED packaging structure, LED module and electronic equipment". This utility model technology provides a breakthrough design of an integrated packaging solution for the field of LED display. Its core structure includes a substrate, a bowl holder and a specially designed LED chip: the substrate is provided with a negative electrode pad and a plurality of independent positive electrode pads, and the bowl holder carries the chip; the chip grows red, green and blue epitaxial layers through the substrate, and each color P-type electrode is connected to the independent positive electrode pad respectively, and the N-type electrode is uniformly connected to the negative electrode pad. This design not only achieves full-color display on a single chip, but also independently controls the luminescent intensity of the red, green and blue epitaxial layers, providing a new technical path for highly integrated display devices.

Qianzhao Optoelectronics: Laser irradiation technology innovates chip preparation process

Jiangxi Qianzhao Optoelectronics announced a patent for" a Micro-LED chip, its preparation method and display device on May 9". The invention processes the wafer through laser irradiation and innovatively uses a patterned dielectric layer to protect the multiple quantum well layer, so that the uncovered areas lose their luminescent characteristics under laser modification, thereby directly defining the Micro LED chip array. This technology avoids the risk of damage caused by traditional ICP etching, eliminates the need to preset the single chip size and sidewall passivation process, significantly reduces manufacturing costs, and shows broad application potential in future ultra-high definition displays, optical communications and optical interconnections.

Xinying Optoelectronics and Xinxiang Optoelectronics: Composite diffusion powder optimizes packaging light emission effect

On the same day, a patent for" a Micro LED panel packaging structure and packaging adhesive jointly applied" by Xinying Optoelectronics and Xinxiang Optoelectronics was unveiled. This solution proposes a new packaging structure that uses a combination of a light-emitting chip, a sapphire packaging layer and an adhesive layer containing a composite diffusion powder. The diffusion powder is made up of foggy opalescent powder and transparent smooth powder, which can simultaneously achieve light diffusion and brightness improvement: on the one hand, the powder disperses light through reflection, improving the problem of uneven light emission caused by phase separation of the packaging materials; On the other hand, the larger total reflection angle between the diffusion powder and the sapphire layer is used to promote light refraction and exit and optimize overall display performance.

Xida Electronics: Optimization of drive system to achieve low-gray display uniformity

On May 6," an active Micro-LED display control system from Sida Electronics" was granted a patent authorization. The system converts MIPI format video data into data voltages through a display driver IC, and generates three control signals based on specific frequency parameters: the GOUT1 signal controls the TFT switching time and accurately adjusts the LED light-emitting time; the GOUT2 and GOUT3 signals cooperate to generate line scan signals to achieve image display. This technology effectively reduces the complexity of system development, ensures the transition uniformity of Micro LED displays when displaying low gray levels, and supports high gray levels of picture output.

Guoxing Semiconductor: Simplifying electrode fan-out process and improving module preparation efficiency

On April 25, Guoxing Semiconductor disclosed" a patent for a Micro LED module and its preparation method". Its innovative process achieves efficient fan-out and routing of microchip electrodes by preparing flattening layers, fan-out electrodes, isolation layers and metal electrode layers step by step. This method uses a flat layer to fill the chip gap and be flush with the electrodes. In conjunction with the thickness control of the isolation layer and the electrode layer, it significantly simplifies the Micro LED module preparation process while ensuring electrical performance and provides technical support for large-scale production.

Mai Yun shows: Microfluidics and dielectrophoresis technology breaks through the bottleneck of transfer accuracy

On the same day, Mai Yun Display launched" a patent for a Micro LED fluid assembly method based on microfluidic and dielectrophoresis". The method prepares Micro LED chips into hydrogel microspheres, after liquid suspension and performance sorting, and uses dielectrophoretic traps to achieve precise positioning and assembly: first, the microspheres are evenly distributed on the target substrate, and then they are orderly captured and released by dielectrophoretic force to form a large-scale array. This technology significantly improves the transfer efficiency and positioning accuracy of Micro LED chips, simplifies traditional transfer processes, reduces production costs, and is expected to accelerate the industrialization process of Micro LED displays.

The concentrated emergence of these patent achievements marks a collective breakthrough for domestic companies in the field of Micro LED technology research and development. Through differentiated innovation strategies, a complete technology chain from chip manufacturing to system integration has been gradually built, providing a basis for the commercialization of Micro LED display technology. Inject strong power.

Zhaochi Semiconductor: Innovative packaging structure achieves single-core full-color display

On May 6, Zhaochi Semiconductor disclosed" patents on Micro LED packaging structure, LED module and electronic equipment". This utility model technology provides a breakthrough design of an integrated packaging solution for the field of LED display. Its core structure includes a substrate, a bowl holder and a specially designed LED chip: the substrate is provided with a negative electrode pad and a plurality of independent positive electrode pads, and the bowl holder carries the chip; the chip grows red, green and blue epitaxial layers through the substrate, and each color P-type electrode is connected to the independent positive electrode pad respectively, and the N-type electrode is uniformly connected to the negative electrode pad. This design not only achieves full-color display on a single chip, but also independently controls the luminescent intensity of the red, green and blue epitaxial layers, providing a new technical path for highly integrated display devices.

Qianzhao Optoelectronics: Laser irradiation technology innovates chip preparation process

Jiangxi Qianzhao Optoelectronics announced a patent for" a Micro-LED chip, its preparation method and display device on May 9". The invention processes the wafer through laser irradiation and innovatively uses a patterned dielectric layer to protect the multiple quantum well layer, so that the uncovered areas lose their luminescent characteristics under laser modification, thereby directly defining the Micro LED chip array. This technology avoids the risk of damage caused by traditional ICP etching, eliminates the need to preset the single chip size and sidewall passivation process, significantly reduces manufacturing costs, and shows broad application potential in future ultra-high definition displays, optical communications and optical interconnections.

Xinying Optoelectronics and Xinxiang Optoelectronics: Composite diffusion powder optimizes packaging light emission effect

On the same day, a patent for" a Micro LED panel packaging structure and packaging adhesive jointly applied" by Xinying Optoelectronics and Xinxiang Optoelectronics was unveiled. This solution proposes a new packaging structure that uses a combination of a light-emitting chip, a sapphire packaging layer and an adhesive layer containing a composite diffusion powder. The diffusion powder is made up of foggy opalescent powder and transparent smooth powder, which can simultaneously achieve light diffusion and brightness improvement: on the one hand, the powder disperses light through reflection, improving the problem of uneven light emission caused by phase separation of the packaging materials; On the other hand, the larger total reflection angle between the diffusion powder and the sapphire layer is used to promote light refraction and exit and optimize overall display performance.

Xida Electronics: Optimization of drive system to achieve low-gray display uniformity

On May 6," an active Micro-LED display control system from Sida Electronics" was granted a patent authorization. The system converts MIPI format video data into data voltages through a display driver IC, and generates three control signals based on specific frequency parameters: the GOUT1 signal controls the TFT switching time and accurately adjusts the LED light-emitting time; the GOUT2 and GOUT3 signals cooperate to generate line scan signals to achieve image display. This technology effectively reduces the complexity of system development, ensures the transition uniformity of Micro LED displays when displaying low gray levels, and supports high gray levels of picture output.

Guoxing Semiconductor: Simplifying electrode fan-out process and improving module preparation efficiency

On April 25, Guoxing Semiconductor disclosed" a patent for a Micro LED module and its preparation method". Its innovative process achieves efficient fan-out and routing of microchip electrodes by preparing flattening layers, fan-out electrodes, isolation layers and metal electrode layers step by step. This method uses a flat layer to fill the chip gap and be flush with the electrodes. In conjunction with the thickness control of the isolation layer and the electrode layer, it significantly simplifies the Micro LED module preparation process while ensuring electrical performance and provides technical support for large-scale production.

Mai Yun shows: Microfluidics and dielectrophoresis technology breaks through the bottleneck of transfer accuracy

On the same day, Mai Yun Display launched" a patent for a Micro LED fluid assembly method based on microfluidic and dielectrophoresis". The method prepares Micro LED chips into hydrogel microspheres, after liquid suspension and performance sorting, and uses dielectrophoretic traps to achieve precise positioning and assembly: first, the microspheres are evenly distributed on the target substrate, and then they are orderly captured and released by dielectrophoretic force to form a large-scale array. This technology significantly improves the transfer efficiency and positioning accuracy of Micro LED chips, simplifies traditional transfer processes, reduces production costs, and is expected to accelerate the industrialization process of Micro LED displays.

The concentrated emergence of these patent achievements marks a collective breakthrough for domestic companies in the field of Micro LED technology research and development. Through differentiated innovation strategies, a complete technology chain from chip manufacturing to system integration has been gradually built, providing a basis for the commercialization of Micro LED display technology. Inject strong power.

TAG:

Guess you want to see it

Popular information

-

CEO of TV IKLAN Group, Indonesia's largest media company, led a delegation to inspect MNLED and the

-

Liard·virtual moving point OptiTrack helps exoskeleton robots start a new journey of rehabilitation

-

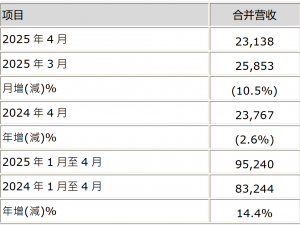

AUO Optronics 'consolidated revenue in April 2025 was 23.1 billion yuan

-

Standing young at 30: Riyadh celebrations kick off a new journey and draw a new blueprint for audio-

-

Guoxing Optoelectronics: Using innovation as a pen to draw a new blueprint for the integrated develo

-

Zhouming Technology and Yunzhihui Technology have reached strategic cooperation to jointly build a n

-

Aixinwei and BOE join hands to create new glory in intelligent interactive equipment

-

Abbison and Bocai join hands to create the world's largest single LED virtual studio: Cold thinking

-

Abbison appeared at the 2025 Tokyo Outdoor Advertising Conference, using LED+AI technology to promot

-

BOE MLED shines in ISE 2025, leading new changes in display technology

the charts

- CEO of TV IKLAN Group, Indonesia's largest media company, led a delegation to inspect MNLED and the

- Innolux joins hands with Yuantai, TPV and others to introduce large size color electronic paper into

- Xida Electronics signs a strategic cooperation agreement with Changbai Mountain Chixi District Manag

- Liard joins hands with "Three-Body" to open a new era of science fiction drama in China

- Zhaochi Semiconductor joins hands with Li Xing Semiconductor. Want to do big things?

- Zhou Ming joins hands with the Guangdong Basketball Association to produce another masterpiece! The

- ISE2023 Abbison's first exhibition in the new year has received frequent good news, and the immersiv

- Samsung Display and APS "work together" to create 3500ppi Micro OLED

- Zhouming Technology and Perfect World officially reached an educational ecological partnership!

- Longli Technology:Mini-LED has been shipped in batches to some in-vehicle customers, VR customers, e