7 powerful ways to make LED display circuit board maintenance no longer difficult

- author:

- 2024-06-07 13:33:48

In the field of electronic equipment maintenance, LED display repair circuit board technology is a crucial skill. Understanding and mastering various maintenance techniques and methods is of great significance for quickly and accurately solving circuit board faults. This article will elaborate on various aspects of LED display repair circuit board technology, including the identification and maintenance methods of capacitors, resistors, and operational amplifiers, as well as some practical tips and analysis skills for specific faults.

Faults caused by damage to capacitors are the highest among electronic equipment, especially damage to electrolytic capacitors is the most common.

电容损坏引发的故障在电子设备中是最高的,其中尤其以电解电容的损坏最为常见。

Capacitor damage is manifested as: 1. Capacity becomes smaller;2. Capacity is completely lost;3. Leakage;4. Short circuit.

technology| 7 tricks for LED display repair circuit board technology

02 Characteristics and discrimination of resistance damage

I often see many beginners struggling with the resistor when repairing the circuit board, removing and soldering it. In fact, if you repair it too much, as long as you understand the damage characteristics of the resistor, you don't have to go to great lengths.

Resistors are the largest number of components in electrical equipment, but they are not the components with the highest damage rate. The most common resistor damage is open circuit, it is rare for the resistance to increase, and it is rare for the resistance to decrease. Common ones are carbon film resistors, metal film resistors, wire wound resistors and insurance resistors.

We can first observe whether the low-value resistors on the circuit board have any traces of blackening. Then, based on the characteristics that most of the resistors are open or the resistance becomes large when the resistors are damaged, and the resistance of high-value resistors are easy to be damaged, we can use a multimeter to measure the resistance values at both ends of the high-value resistor directly on the circuit board. If the measured resistance is greater than the nominal resistance, the resistor will definitely be damaged.(Pay attention to wait until the resistance value display stabilizes before reaching a conclusion, because there may be a charging and discharging process in the circuit.) If the measured resistance value is smaller than the nominal resistance value, it is generally ignored. In this way, every resistor on the circuit board is measured, and even if a thousand are killed by mistake, one will not be spared.

technology| 7 tricks for LED display repair circuit board technology

03 Method to judge whether an operational amplifier is good or bad

Amplifiers have the characteristics of" virtual short" and" virtual interruption", which are very useful for analyzing operational amplifier circuits for linear applications. In order to ensure linear operation, the op amp must operate in a closed loop (negative feedback). Without negative feedback, the op amp under open-loop amplification becomes a comparator. If you want to judge the quality of a device, you should first distinguish whether the device is used as an amplifier or a comparator in the circuit.

According to the principle of virtual short amplifiers, that is to say, if this operational amplifier works normally, the voltages at the same input and inverting input terminals must be equal. Even if there is a difference, it will be mv level. Of course, in some high input impedance circuits, The internal resistance of the multimeter will have a slight impact on the voltage test, but generally it will not exceed 0.2V. If there is a difference of more than 0.5V, the amplifier will undoubtedly be damaged!

If the device is used as a comparator, the non-inverting input terminal and the inverting input terminal are allowed to be unequal,

If the in-direction voltage> the reverse voltage, the output voltage is close to the positive maximum value; if the in-direction voltage

This way, you can judge whether the operational amplifier is good or bad without using substitution methods or removing the chip on the circuit board.

Some patch components are very small, which is inconvenient to use ordinary multimeter probes to test and maintain. First, it is easy to cause a short circuit, and second, it is inconvenient for a circuit board coated with an insulating coating to come into contact with the metal part of the component pins.

有些贴片元件非常细小,用普通万用表表笔测试检修时很不方便,一是容易造成短路,二是对涂有绝缘涂层的电路板不便接触到元件管脚的金属部分。Here is a simple method that will bring a lot of convenience to testing.

Take the two smallest sewing needles and tie them tightly with a multimeter pen (in-depth industrial control maintenance technology column). Then take a thin copper wire from a multi-strand cable, tie the needles and the sewing needles with thin copper wire, and then weld them firmly with solder. In this way, when using probes with small tips to measure those SMT components, there is no longer any risk of short circuits, and the tips can pierce the insulating coating and hit key parts, eliminating the need to bother scraping those films.

05 Maintenance method for short circuit failure of public power supply of circuit board

During circuit board maintenance, if you encounter a short circuit in the public power supply, it is often a big problem, because many devices share the same power supply, and every device using this power supply is suspected of being short. If there are not many components on the board, you can use" hoeing". The method can eventually find the short circuit point. If there are too many components,"" whether hoeing can get the situation depends on luck. Here, I recommend a more effective method. Using this method, you can get twice the result with half the effort and often find the fault point quickly.

You need to have a power supply with adjustable voltage and current, with a voltage of 0- 30V and a current of 0-3A. This power supply is not expensive, about 300 yuan. Adjust the open-circuit voltage to the device's power supply voltage level, first adjust the current to a minimum, add this voltage to the power supply voltage points of the circuit, such as the 5V and 0V terminals of the 74 series chip. Depending on the degree of the short circuit, slowly increase the current, and touch the device with your hands. When you touch a device that is obviously hot, this is often a damaged component, which can be removed for further measurement and confirmation. Of course, the voltage during operation must not exceed the working voltage of the device, and it must not be connected in reverse, otherwise other good devices will be burned out.

06 A small eraser solves big problems

More and more boards are used in industrial control, and many boards use gold fingers inserted into slots. Due to the harsh environment of the industrial site, the dusty, humid, and corrosive gas environment can easily cause poor contact failures on the board. Many friends may have solved the problem by replacing the board, but the cost of purchasing the board is very considerable, especially the board of some imported equipment. In fact, you may wish to use an eraser to rub the gold finger repeatedly a few times. After cleaning up the dirt on the gold finger, try again, and the problem may be solved! The method is simple and practical.

Analysis of electrical faults at good times and bad times in 07

Various electrical faults, good and bad, may include the following situations in terms of probability:

1. Poor contact

Poor contact between the card and the slot, disconnection and failure of the cable when the internal part is broken, poor contact between wire plugs and terminal terminals, and false welding of components and components all fall into this category;

2. Signal interference

For digital circuits, faults will appear only under certain circumstances and conditions. It may be that too much interference affects the control system and causes it to go wrong. There may also be changes in the parameters of individual components or overall performance parameters of the circuit board, making it anti-interference The ability tends to a critical point, resulting in a failure;

3. Poor thermal stability of components

Judging from a large number of maintenance practices, the first one is that the thermal stability of electrolytic capacitors is poor, followed by other capacitors, transistors, diodes, ICs, resistors, etc.;

4. Moisture, dust, etc. on the circuit board.

Moisture and accumulated dust conduct electricity and have a resistance effect, and the resistance value will change during the process of thermal expansion and contraction. This resistance value has a parallel effect with other components. When this effect is strong, circuit parameters will be changed and faults will occur.;

5. Software is also a consideration

Many parameters in the circuit are adjusted using software, and the margins of some parameters are adjusted too low and are in a critical range. When the operating conditions of the machine comply with the reason for the software to determine the fault, an alarm will appear.

In short, mastering these tough techniques for LED display maintenance circuit board technology is of great significance to improving maintenance efficiency and accuracy. In actual operation, it is necessary to continuously accumulate experience and flexibly use various methods and techniques to deal with various complex circuit board fault situations. I hope this article can provide useful reference and help for maintenance personnel and make everyone more comfortable on the road to repairing circuit boards.

Faults caused by damage to capacitors are the highest among electronic equipment, especially damage to electrolytic capacitors is the most common.

电容损坏引发的故障在电子设备中是最高的,其中尤其以电解电容的损坏最为常见。

Capacitor damage is manifested as: 1. Capacity becomes smaller;2. Capacity is completely lost;3. Leakage;4. Short circuit.

technology| 7 tricks for LED display repair circuit board technology

02 Characteristics and discrimination of resistance damage

I often see many beginners struggling with the resistor when repairing the circuit board, removing and soldering it. In fact, if you repair it too much, as long as you understand the damage characteristics of the resistor, you don't have to go to great lengths.

Resistors are the largest number of components in electrical equipment, but they are not the components with the highest damage rate. The most common resistor damage is open circuit, it is rare for the resistance to increase, and it is rare for the resistance to decrease. Common ones are carbon film resistors, metal film resistors, wire wound resistors and insurance resistors.

We can first observe whether the low-value resistors on the circuit board have any traces of blackening. Then, based on the characteristics that most of the resistors are open or the resistance becomes large when the resistors are damaged, and the resistance of high-value resistors are easy to be damaged, we can use a multimeter to measure the resistance values at both ends of the high-value resistor directly on the circuit board. If the measured resistance is greater than the nominal resistance, the resistor will definitely be damaged.(Pay attention to wait until the resistance value display stabilizes before reaching a conclusion, because there may be a charging and discharging process in the circuit.) If the measured resistance value is smaller than the nominal resistance value, it is generally ignored. In this way, every resistor on the circuit board is measured, and even if a thousand are killed by mistake, one will not be spared.

technology| 7 tricks for LED display repair circuit board technology

03 Method to judge whether an operational amplifier is good or bad

Amplifiers have the characteristics of" virtual short" and" virtual interruption", which are very useful for analyzing operational amplifier circuits for linear applications. In order to ensure linear operation, the op amp must operate in a closed loop (negative feedback). Without negative feedback, the op amp under open-loop amplification becomes a comparator. If you want to judge the quality of a device, you should first distinguish whether the device is used as an amplifier or a comparator in the circuit.

According to the principle of virtual short amplifiers, that is to say, if this operational amplifier works normally, the voltages at the same input and inverting input terminals must be equal. Even if there is a difference, it will be mv level. Of course, in some high input impedance circuits, The internal resistance of the multimeter will have a slight impact on the voltage test, but generally it will not exceed 0.2V. If there is a difference of more than 0.5V, the amplifier will undoubtedly be damaged!

If the device is used as a comparator, the non-inverting input terminal and the inverting input terminal are allowed to be unequal,

If the in-direction voltage> the reverse voltage, the output voltage is close to the positive maximum value; if the in-direction voltage

This way, you can judge whether the operational amplifier is good or bad without using substitution methods or removing the chip on the circuit board.

Some patch components are very small, which is inconvenient to use ordinary multimeter probes to test and maintain. First, it is easy to cause a short circuit, and second, it is inconvenient for a circuit board coated with an insulating coating to come into contact with the metal part of the component pins.

有些贴片元件非常细小,用普通万用表表笔测试检修时很不方便,一是容易造成短路,二是对涂有绝缘涂层的电路板不便接触到元件管脚的金属部分。Here is a simple method that will bring a lot of convenience to testing.

Take the two smallest sewing needles and tie them tightly with a multimeter pen (in-depth industrial control maintenance technology column). Then take a thin copper wire from a multi-strand cable, tie the needles and the sewing needles with thin copper wire, and then weld them firmly with solder. In this way, when using probes with small tips to measure those SMT components, there is no longer any risk of short circuits, and the tips can pierce the insulating coating and hit key parts, eliminating the need to bother scraping those films.

05 Maintenance method for short circuit failure of public power supply of circuit board

During circuit board maintenance, if you encounter a short circuit in the public power supply, it is often a big problem, because many devices share the same power supply, and every device using this power supply is suspected of being short. If there are not many components on the board, you can use" hoeing". The method can eventually find the short circuit point. If there are too many components,"" whether hoeing can get the situation depends on luck. Here, I recommend a more effective method. Using this method, you can get twice the result with half the effort and often find the fault point quickly.

You need to have a power supply with adjustable voltage and current, with a voltage of 0- 30V and a current of 0-3A. This power supply is not expensive, about 300 yuan. Adjust the open-circuit voltage to the device's power supply voltage level, first adjust the current to a minimum, add this voltage to the power supply voltage points of the circuit, such as the 5V and 0V terminals of the 74 series chip. Depending on the degree of the short circuit, slowly increase the current, and touch the device with your hands. When you touch a device that is obviously hot, this is often a damaged component, which can be removed for further measurement and confirmation. Of course, the voltage during operation must not exceed the working voltage of the device, and it must not be connected in reverse, otherwise other good devices will be burned out.

06 A small eraser solves big problems

More and more boards are used in industrial control, and many boards use gold fingers inserted into slots. Due to the harsh environment of the industrial site, the dusty, humid, and corrosive gas environment can easily cause poor contact failures on the board. Many friends may have solved the problem by replacing the board, but the cost of purchasing the board is very considerable, especially the board of some imported equipment. In fact, you may wish to use an eraser to rub the gold finger repeatedly a few times. After cleaning up the dirt on the gold finger, try again, and the problem may be solved! The method is simple and practical.

Analysis of electrical faults at good times and bad times in 07

Various electrical faults, good and bad, may include the following situations in terms of probability:

1. Poor contact

Poor contact between the card and the slot, disconnection and failure of the cable when the internal part is broken, poor contact between wire plugs and terminal terminals, and false welding of components and components all fall into this category;

2. Signal interference

For digital circuits, faults will appear only under certain circumstances and conditions. It may be that too much interference affects the control system and causes it to go wrong. There may also be changes in the parameters of individual components or overall performance parameters of the circuit board, making it anti-interference The ability tends to a critical point, resulting in a failure;

3. Poor thermal stability of components

Judging from a large number of maintenance practices, the first one is that the thermal stability of electrolytic capacitors is poor, followed by other capacitors, transistors, diodes, ICs, resistors, etc.;

4. Moisture, dust, etc. on the circuit board.

Moisture and accumulated dust conduct electricity and have a resistance effect, and the resistance value will change during the process of thermal expansion and contraction. This resistance value has a parallel effect with other components. When this effect is strong, circuit parameters will be changed and faults will occur.;

5. Software is also a consideration

Many parameters in the circuit are adjusted using software, and the margins of some parameters are adjusted too low and are in a critical range. When the operating conditions of the machine comply with the reason for the software to determine the fault, an alarm will appear.

In short, mastering these tough techniques for LED display maintenance circuit board technology is of great significance to improving maintenance efficiency and accuracy. In actual operation, it is necessary to continuously accumulate experience and flexibly use various methods and techniques to deal with various complex circuit board fault situations. I hope this article can provide useful reference and help for maintenance personnel and make everyone more comfortable on the road to repairing circuit boards.

TAG:

Guess you want to see it

Popular information

-

From modules to large screens, the entire process of LED display installation is introduced

-

Analysis of six characteristics of LED display application phenomena

-

7 powerful ways to make LED display circuit board maintenance no longer difficult

-

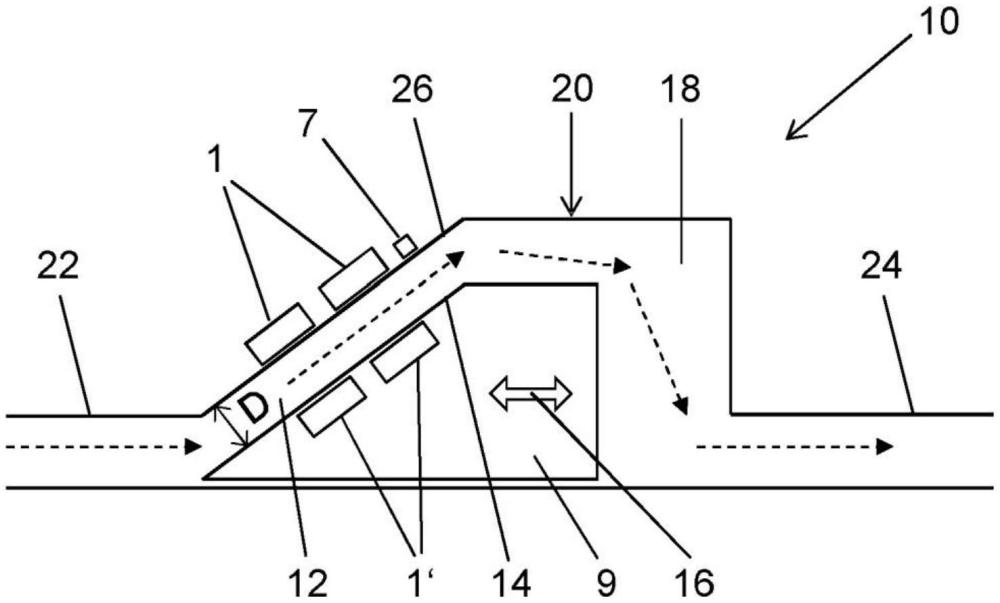

To solve 2 problems, Octavia Optoelectronics and Ames Osram announced new patents

-

Introduction to LED process technology--Application of LED display driver chips

-

Efficient and reliable quantum dot white LED packaging and thermal management

-

What kind of LED full-color screen can meet indoor and outdoor needs?

-

Analysis of factors affecting display prices

-

What are the quality and installation requirements for installing LED displays in multi-functional s

-

Evolution history of led displays from monochrome to full-color to small-pitch

the charts

- Liaocheng University and Soochow University collaborate to make progress in the research field of bl

- Hot research! How will the future development of LED displays achieve a leap?

- How to better select and use dedicated LEDs for full-color displays

- Introduction to LED process technology--Application of LED display driver chips

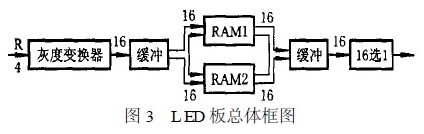

- Design of grayscale display scheme for HD LED display

- A new method for detecting brightness and chroma of outdoor full-color LED display

- Analysis of six characteristics of LED display application phenomena

- What are the quality and installation requirements for installing LED displays in multi-functional s

- What kind of LED full-color screen can meet indoor and outdoor needs?

- Analysis of factors affecting display prices