Causes and solutions to LED display control card failures

- author:

- 2024-06-07 13:42:40

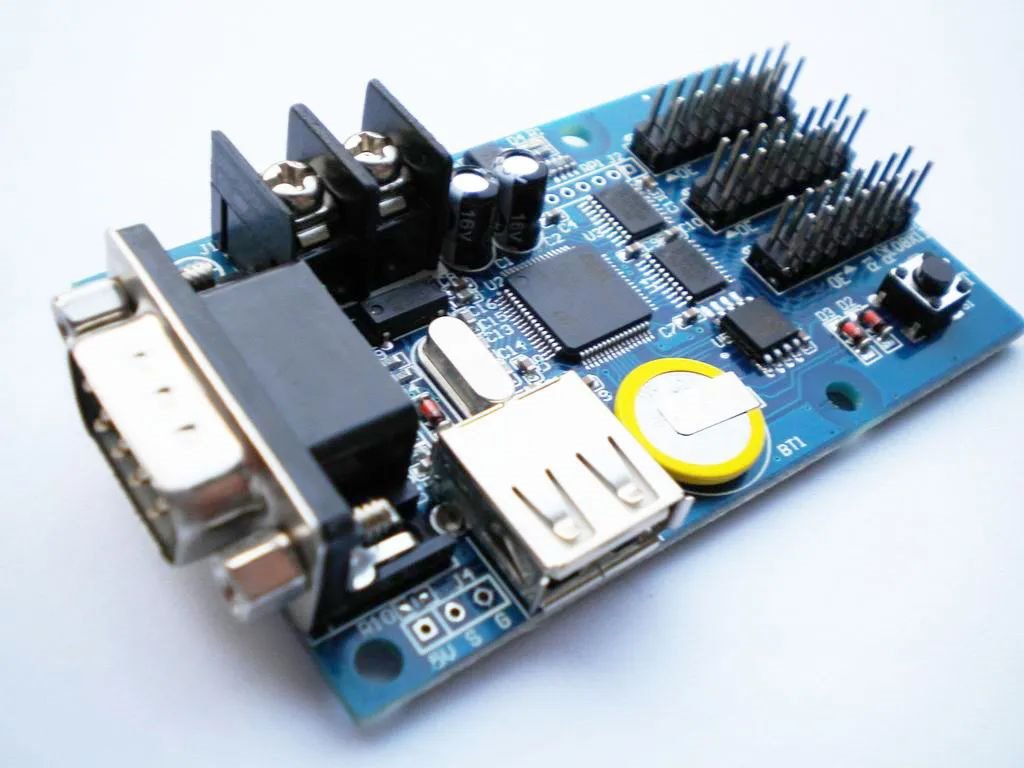

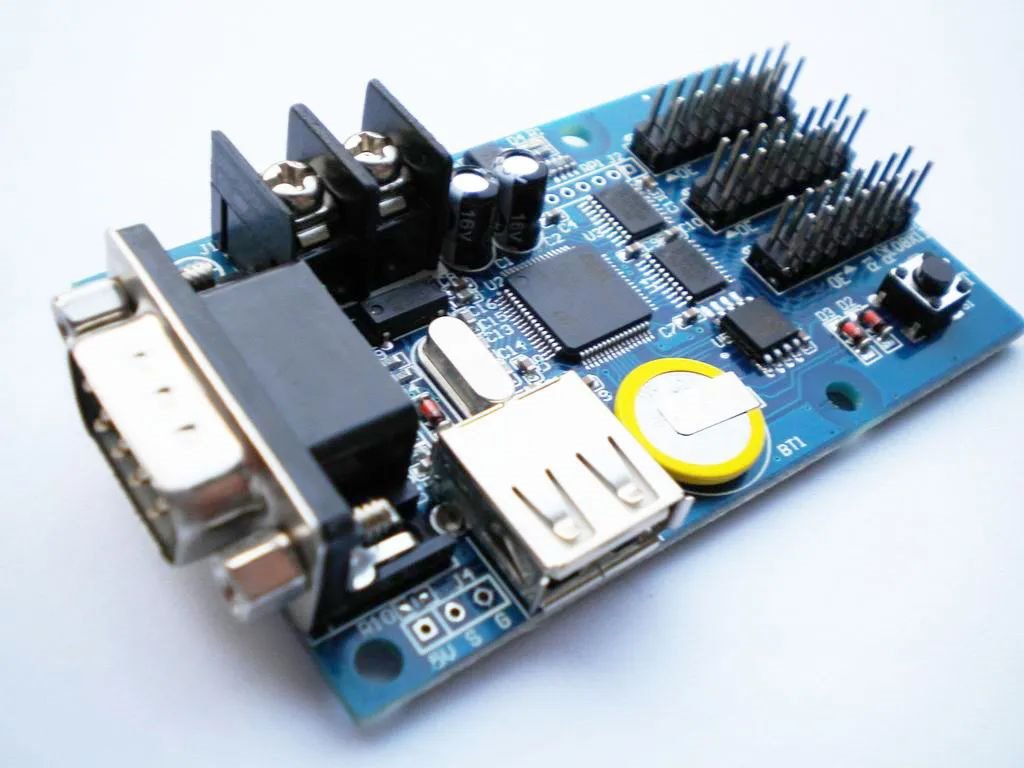

In the operation of LED displays, the control card plays a vital role as a core component. It undertakes the key tasks of receiving screen display information, placing it in frame memory, and generating the required display data and scan control timing. Understanding the working principle of the LED display control card, common faults and solutions is of great significance to ensuring the normal operation and maintenance of the display.

The LED display control card is the core component of the LED graphic display. It is mainly responsible for receiving the screen display information from the computer's serial port, placing it in the frame memory, and generating the serial display data and scanning control timing required by the LED display according to the partition driving method. We can see the importance of LED display control cards from the word core components. What should I do if the system cannot detect the LED control card? Come and learn with Xiaobian.

01 如何判断 LED 控制卡处在正常工作状态下?

控制卡接通电源后,请先观察电源指示灯,红灯亮表示 5V 电压已接上,若不亮请立即关闭 5V 电源。Check whether the 5V working voltage is properly connected, whether it is overvoltage, reverse connection, failure, output short circuit, etc. Please use a separate 5V power supply to power the control card. If the red light is not on, it needs to be repaired.

technology| Causes and solutions for LED display control card failure

01 General steps to resolve LED control card failures

1. Confirm that the control card is compatible with the software.

2. Check whether the connecting cable is detached or loose, check and confirm that the serial cable used to connect the control card matches the control card. Some control cards use direct (2-2, 3-3, 5-5), and some control cards use (2-3, 3-2, 5-5).

3. Ensure that the control system hardware is powered up correctly.

4. Select the correct product model, correct transmission method, correct serial port number, and correct baud rate by comparing the control card software with the control card you choose, and correctly set the control system hardware by comparing the dial switch diagram provided in the software. Address bits and baud rate.

5. If the loading still fails after the above inspection and correction, please use a multimeter to measure whether the serial port of the connected computer or control system hardware is damaged to confirm whether it should be returned to the computer manufacturer or the control system hardware for testing.

6. If step 5 is not convenient, please contact the manufacturer to provide technical support.

02 Common phenomena of LED control card failure

Phenomenon 1: After connecting and powering on, only some programs are played, then playback is stopped, and playback is restarted.

The main reason is that the power supply is not enough and the control card automatically restarts. The solutions are: 1. Reduce the brightness;2. The power supply with the control card has two fewer unit boards;3. Increase the power supply.

Phenomenon 2: When the control card is normal, the display screen has no display or abnormal brightness

After the control card is connected to the display driver and is powered on, the default is 16 scans. If there is no display, please check whether the data polarity and OE polarity settings in the control software are correct; if the brightness is abnormal and one line is particularly bright, indicating that the OE setting is reversed. Please set OE correctly.

Phenomenon 3: When transferring information to the control card, the system prompts" an error and the transfer fails"

Please check whether the communication interface is connected correctly, whether the jumper on the control card jumps at the corresponding level, and"" whether the parameters in the control card settings are correct. Also, if the working voltage is too low, please use a multimeter to test, and ensure that the voltage is above 4.5V.

Phenomenon 4: After the information is loaded, the display cannot display normally

Check"" whether the scan output selection in the control card settings is correct.

Phenomenon 5: Communication is not smooth when 485 is networking

Please check whether the connection method of the communication cable is correct. Connect the communication cables of each screen to the computer interface by mistake. This will generate strong reflected waves and cause serious interference to the transmitted signal. Correct connection method should be adopted. See "Communication Interface Use and Precautions" for details.

03 How to solve poor communication when using GSM data transmission and remote dialing?

First check whether there is a problem with the MODEM, disconnect the MODEM connected to the control card, and connect this MODEM to another computer, so that the MODEMs at the sender and receiver are both connected to the computer and separated from the control system. Download a software called Serial Debugging Assistant from the Internet, and use it to set up and debug MODEM after installation. First, set the MODEM at the receiving end to automatic response. The setting method is: turn on the serial debugging assistant at both ends, and enter ATS0 =1 in the serial debugging assistant at the receiving end to enter. This command can set the MODEM at the receiving end to automatic response. If the setting is successful, the AA indicator light on the MODEM will light up. If it does not light up, the setting will not be successful. Please check whether the MODEM is connected correctly to the computer and whether the MODEM is powered on.

After the automatic answer is set successfully, the debugging assistant enters the" phone number of the receiver at the serial port of the sender, enters the enter", and dials the receiver. At this time, some information can be transferred from the sender to the receiver, and some information can be transferred from the receiver to the sender. If the information received at both ends is normal, the communication connection has been established, and the CD indicator on the MODEM will light up. If the above processes are normal, it proves that MODEM communication is normal and there are no problems.

After checking that there are no problems with MODEM, if communication is still not smooth, the problem may be caused by the control card settings. Connect MODEM to the control card, open the control card setting software at the sender, click Read Back Settings, check whether the serial port baud rate, serial port, protocol and other settings are correct, and click Write Settings after making changes. Open the Offline King software, set the corresponding communication interface methods and parameters in the communication method, and finally transfer the script.

Ending:

In short, troubleshooting and solving the LED display control card requires us to carefully analyze and gradually investigate, and master the correct methods and skills. By understanding the causes of common failures and familiarizing ourselves with corresponding solutions, we can better ensure the stable operation of LED displays and give full play to its important role in information display and other aspects. At the same time, when encountering complex problems, it is also very important to communicate with manufacturers in a timely manner to obtain professional support. I hope this article can provide useful reference and help when dealing with problems related to LED display control cards.

The LED display control card is the core component of the LED graphic display. It is mainly responsible for receiving the screen display information from the computer's serial port, placing it in the frame memory, and generating the serial display data and scanning control timing required by the LED display according to the partition driving method. We can see the importance of LED display control cards from the word core components. What should I do if the system cannot detect the LED control card? Come and learn with Xiaobian.

01 如何判断 LED 控制卡处在正常工作状态下?

控制卡接通电源后,请先观察电源指示灯,红灯亮表示 5V 电压已接上,若不亮请立即关闭 5V 电源。Check whether the 5V working voltage is properly connected, whether it is overvoltage, reverse connection, failure, output short circuit, etc. Please use a separate 5V power supply to power the control card. If the red light is not on, it needs to be repaired.

technology| Causes and solutions for LED display control card failure

01 General steps to resolve LED control card failures

1. Confirm that the control card is compatible with the software.

2. Check whether the connecting cable is detached or loose, check and confirm that the serial cable used to connect the control card matches the control card. Some control cards use direct (2-2, 3-3, 5-5), and some control cards use (2-3, 3-2, 5-5).

3. Ensure that the control system hardware is powered up correctly.

4. Select the correct product model, correct transmission method, correct serial port number, and correct baud rate by comparing the control card software with the control card you choose, and correctly set the control system hardware by comparing the dial switch diagram provided in the software. Address bits and baud rate.

5. If the loading still fails after the above inspection and correction, please use a multimeter to measure whether the serial port of the connected computer or control system hardware is damaged to confirm whether it should be returned to the computer manufacturer or the control system hardware for testing.

6. If step 5 is not convenient, please contact the manufacturer to provide technical support.

02 Common phenomena of LED control card failure

Phenomenon 1: After connecting and powering on, only some programs are played, then playback is stopped, and playback is restarted.

The main reason is that the power supply is not enough and the control card automatically restarts. The solutions are: 1. Reduce the brightness;2. The power supply with the control card has two fewer unit boards;3. Increase the power supply.

Phenomenon 2: When the control card is normal, the display screen has no display or abnormal brightness

After the control card is connected to the display driver and is powered on, the default is 16 scans. If there is no display, please check whether the data polarity and OE polarity settings in the control software are correct; if the brightness is abnormal and one line is particularly bright, indicating that the OE setting is reversed. Please set OE correctly.

Phenomenon 3: When transferring information to the control card, the system prompts" an error and the transfer fails"

Please check whether the communication interface is connected correctly, whether the jumper on the control card jumps at the corresponding level, and"" whether the parameters in the control card settings are correct. Also, if the working voltage is too low, please use a multimeter to test, and ensure that the voltage is above 4.5V.

Phenomenon 4: After the information is loaded, the display cannot display normally

Check"" whether the scan output selection in the control card settings is correct.

Phenomenon 5: Communication is not smooth when 485 is networking

Please check whether the connection method of the communication cable is correct. Connect the communication cables of each screen to the computer interface by mistake. This will generate strong reflected waves and cause serious interference to the transmitted signal. Correct connection method should be adopted. See "Communication Interface Use and Precautions" for details.

03 How to solve poor communication when using GSM data transmission and remote dialing?

First check whether there is a problem with the MODEM, disconnect the MODEM connected to the control card, and connect this MODEM to another computer, so that the MODEMs at the sender and receiver are both connected to the computer and separated from the control system. Download a software called Serial Debugging Assistant from the Internet, and use it to set up and debug MODEM after installation. First, set the MODEM at the receiving end to automatic response. The setting method is: turn on the serial debugging assistant at both ends, and enter ATS0 =1 in the serial debugging assistant at the receiving end to enter. This command can set the MODEM at the receiving end to automatic response. If the setting is successful, the AA indicator light on the MODEM will light up. If it does not light up, the setting will not be successful. Please check whether the MODEM is connected correctly to the computer and whether the MODEM is powered on.

After the automatic answer is set successfully, the debugging assistant enters the" phone number of the receiver at the serial port of the sender, enters the enter", and dials the receiver. At this time, some information can be transferred from the sender to the receiver, and some information can be transferred from the receiver to the sender. If the information received at both ends is normal, the communication connection has been established, and the CD indicator on the MODEM will light up. If the above processes are normal, it proves that MODEM communication is normal and there are no problems.

After checking that there are no problems with MODEM, if communication is still not smooth, the problem may be caused by the control card settings. Connect MODEM to the control card, open the control card setting software at the sender, click Read Back Settings, check whether the serial port baud rate, serial port, protocol and other settings are correct, and click Write Settings after making changes. Open the Offline King software, set the corresponding communication interface methods and parameters in the communication method, and finally transfer the script.

Ending:

In short, troubleshooting and solving the LED display control card requires us to carefully analyze and gradually investigate, and master the correct methods and skills. By understanding the causes of common failures and familiarizing ourselves with corresponding solutions, we can better ensure the stable operation of LED displays and give full play to its important role in information display and other aspects. At the same time, when encountering complex problems, it is also very important to communicate with manufacturers in a timely manner to obtain professional support. I hope this article can provide useful reference and help when dealing with problems related to LED display control cards.

TAG:

Guess you want to see it

Popular information

-

Evolution history of led displays from monochrome to full-color to small-pitch

-

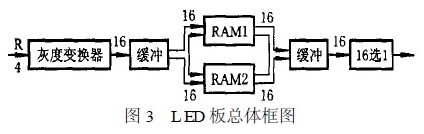

Design of grayscale display scheme for HD LED display

-

Hot research! How will the future development of LED displays achieve a leap?

-

From modules to large screens, the entire process of LED display installation is introduced

-

Technical Chapter| What do you know about LED display device packaging technology?

-

Introduction to LED process technology--Application of LED display driver chips

-

To solve 2 problems, Octavia Optoelectronics and Ames Osram announced new patents

-

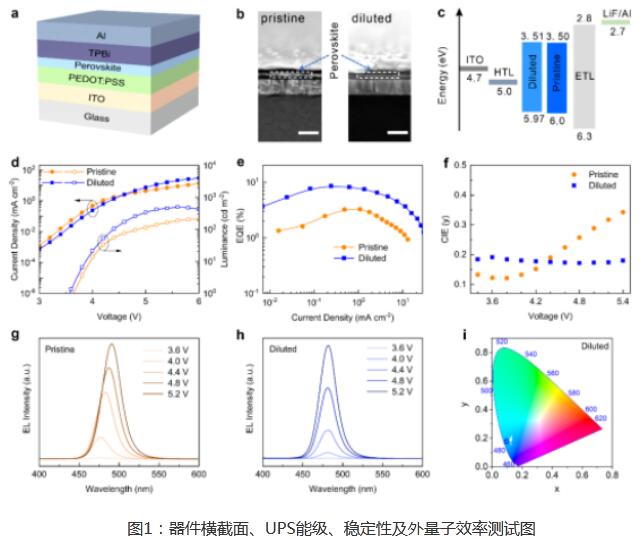

Liaocheng University and Soochow University collaborate to make progress in the research field of bl

-

What are the quality and installation requirements for installing LED displays in multi-functional s

-

7 powerful ways to make LED display circuit board maintenance no longer difficult

the charts

- Liaocheng University and Soochow University collaborate to make progress in the research field of bl

- Hot research! How will the future development of LED displays achieve a leap?

- How to better select and use dedicated LEDs for full-color displays

- Introduction to LED process technology--Application of LED display driver chips

- Design of grayscale display scheme for HD LED display

- A new method for detecting brightness and chroma of outdoor full-color LED display

- Analysis of six characteristics of LED display application phenomena

- What are the quality and installation requirements for installing LED displays in multi-functional s

- What kind of LED full-color screen can meet indoor and outdoor needs?

- Analysis of factors affecting display prices