Liard's new generation high-end MIP production line: A major breakthrough and transformation in the

- author:

- 2024-11-28 10:03:33

In the era of rapid development of science and technology, the field of display technology has always been at the forefront of continuous change and innovation. On November 20, Liard was like a dazzling star, shining brightly at the Wuxi Lijing factory-its new generation of high-end MIP production line (Micro LED packaging technology) independently developed in the first phase of the entire process was officially put into operation. This milestone event is like dropping a huge stone on a calm lake, arousing thousands of waves. It not only injects strong impetus into Liard's own continuous leadership in the field of Micro LED display technology, but also adds a strong color to the development picture of the entire Micro LED display industry, comprehensively opening a new era of accelerated technological innovation in this field, product cost reduction and efficiency improvement, and large-scale application popularization.

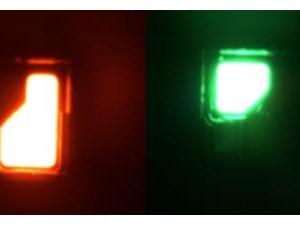

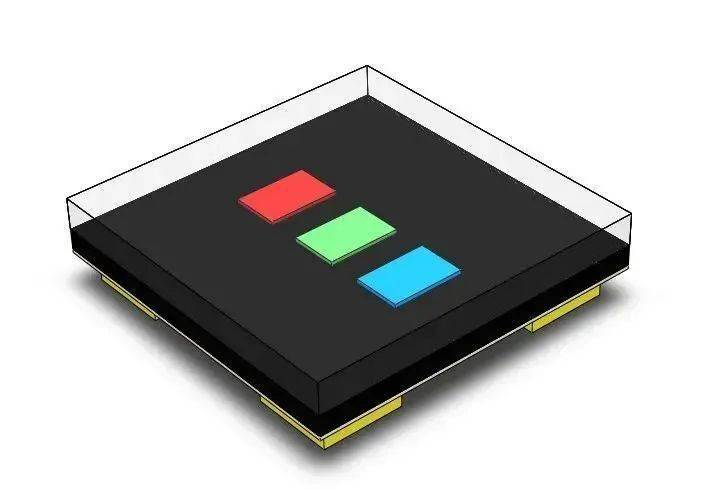

What is Advanced MIP? It is like a work of art carefully carved by an exquisite technological craftsman. It adopts a fully flip-chip substrate-less Micro LED chip less than 50 meters. Its tiny chip area is amazing, less than 1/10 of that of a traditional LED chip, and the light-emitting area is less than 1% of the screen area. Black accounts for as high as 99%. Such a sophisticated design allows the contrast to be greatly improved and presents a clearer, realistic and rich image effect to the audience. In addition, the half-power angle of substrateless RGB LED chips is the same. This feature is like a magical key, perfectly unlocking the problem of large viewing angle display. Even at large angles exceeding 170, the LED screen can still accurately maintain the color temperature and chroma The consistency of viewing angle completely bids farewell to the trouble of color casting problems, allowing every viewing angle to experience the same wonderful picture.

The full-process self-developed high-end MIP production line has many eye-catching advantages. In terms of production environment, the thousand-level clean MIP lamp bead automated production line provides a pure and flawless space guarantee for high-quality product manufacturing. Its automated and intelligent production process is like an efficient and orderly symphony of science and technology, with all links working closely together and flowing smoothly. The huge amount of transfer and welding technology independently developed is the exciting climax of this symphony. The transfer efficiency is as high as 6000kUPH, which is 150 times the efficiency of ordinary die bonders. It is like a superhero, with amazing speed and power promote the realization of cost reduction and efficiency improvement, greatly improving production efficiency, reducing production costs, and making Micro LED products more advantageous in market competition.

From the perspective of production yield, Lijing Microelectronics currently has a huge amount of key process equipment such as transfer, huge amount of welding, huge amount of testing, and huge amount of cutting, which are like loyal guardians, guarding the door to product quality. The yield and efficiency of key stations in the overall production process are higher than the industry average, and the yield of high-end MIP products is>95%. This outstanding achievement is like a solid beacon, providing other companies in the vast sea of the Micro LED industry. The company guides the direction and sets an industry benchmark.

The official commissioning of the first phase of Riadelijing's high-end MIP production line has undoubtedly opened a golden door to the high-definition display market below 1 mm. It will be like a surging wave that will greatly promote the growth of demand in this market and bring Micro LED products with higher cost performance and better display effects to the market. It is estimated that the first phase of high-end MIP production capacity will reach 1200KK /month. This strong production capacity is like a rich treasure, providing sufficient product supply for the market. The second-phase production capacity will be expanded to 2400KK /month, which demonstrates Liard's grand layout and firm confidence in the future market.

At the same time, in order to accelerate progress on the road of large-scale development and promotion of Micro LEDs, Liard is like an intelligent leader who knows the power of cooperation. The company will continue to work together with partners from all parties to jointly promote the mass production application of high-end glass-based MiP products. This strategic decision is like multiple streams gathering into a river. The forces of all parties blend and work together. It will surely draw a more colorful picture in the vast starry sky of the Micro LED industry and bring more excellence to consumers around the world. The display experience leads the entire industry towards a more brilliant future.

What is Advanced MIP? It is like a work of art carefully carved by an exquisite technological craftsman. It adopts a fully flip-chip substrate-less Micro LED chip less than 50 meters. Its tiny chip area is amazing, less than 1/10 of that of a traditional LED chip, and the light-emitting area is less than 1% of the screen area. Black accounts for as high as 99%. Such a sophisticated design allows the contrast to be greatly improved and presents a clearer, realistic and rich image effect to the audience. In addition, the half-power angle of substrateless RGB LED chips is the same. This feature is like a magical key, perfectly unlocking the problem of large viewing angle display. Even at large angles exceeding 170, the LED screen can still accurately maintain the color temperature and chroma The consistency of viewing angle completely bids farewell to the trouble of color casting problems, allowing every viewing angle to experience the same wonderful picture.

The full-process self-developed high-end MIP production line has many eye-catching advantages. In terms of production environment, the thousand-level clean MIP lamp bead automated production line provides a pure and flawless space guarantee for high-quality product manufacturing. Its automated and intelligent production process is like an efficient and orderly symphony of science and technology, with all links working closely together and flowing smoothly. The huge amount of transfer and welding technology independently developed is the exciting climax of this symphony. The transfer efficiency is as high as 6000kUPH, which is 150 times the efficiency of ordinary die bonders. It is like a superhero, with amazing speed and power promote the realization of cost reduction and efficiency improvement, greatly improving production efficiency, reducing production costs, and making Micro LED products more advantageous in market competition.

From the perspective of production yield, Lijing Microelectronics currently has a huge amount of key process equipment such as transfer, huge amount of welding, huge amount of testing, and huge amount of cutting, which are like loyal guardians, guarding the door to product quality. The yield and efficiency of key stations in the overall production process are higher than the industry average, and the yield of high-end MIP products is>95%. This outstanding achievement is like a solid beacon, providing other companies in the vast sea of the Micro LED industry. The company guides the direction and sets an industry benchmark.

The official commissioning of the first phase of Riadelijing's high-end MIP production line has undoubtedly opened a golden door to the high-definition display market below 1 mm. It will be like a surging wave that will greatly promote the growth of demand in this market and bring Micro LED products with higher cost performance and better display effects to the market. It is estimated that the first phase of high-end MIP production capacity will reach 1200KK /month. This strong production capacity is like a rich treasure, providing sufficient product supply for the market. The second-phase production capacity will be expanded to 2400KK /month, which demonstrates Liard's grand layout and firm confidence in the future market.

At the same time, in order to accelerate progress on the road of large-scale development and promotion of Micro LEDs, Liard is like an intelligent leader who knows the power of cooperation. The company will continue to work together with partners from all parties to jointly promote the mass production application of high-end glass-based MiP products. This strategic decision is like multiple streams gathering into a river. The forces of all parties blend and work together. It will surely draw a more colorful picture in the vast starry sky of the Micro LED industry and bring more excellence to consumers around the world. The display experience leads the entire industry towards a more brilliant future.

TAG:

Guess you want to see it

Popular information

-

CEO of TV IKLAN Group, Indonesia's largest media company, led a delegation to inspect MNLED and the

-

Alto Electronics: XR Studio, a brilliant chapter of media transformation and virtual production

-

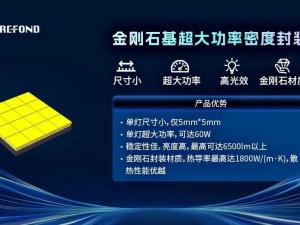

Ruifeng Optoelectronics 'new diamond-based packaging products break through the bottleneck of high-p

-

Skyworth launches A5F Pro Mini LED TV and joins hands with Zhaochi Guangyuan to reshape the high-end

-

Create a new chapter: Xinleguang Mini LED Backlight &Direct Display Industrial Park Phase I producti

-

New experience of watching games in the Chinese Super League: Huaxia Film Center leads the transform

-

Alto Electronics 'global layout takes a new direction: Dubai Representative Office opens grandly

-

TCL Commercial Niu Hailong: TCL Commercial is one of TCL's second growth curves

-

Lehman Optoelectronics empowers Shandong Gold Penglai Mining to create a new benchmark for intellige

-

Liard: The leader of visual effects technology, quality and service create brilliance

the charts

- CEO of TV IKLAN Group, Indonesia's largest media company, led a delegation to inspect MNLED and the

- Innolux joins hands with Yuantai, TPV and others to introduce large size color electronic paper into

- Xida Electronics signs a strategic cooperation agreement with Changbai Mountain Chixi District Manag

- Liard joins hands with "Three-Body" to open a new era of science fiction drama in China

- Zhaochi Semiconductor joins hands with Li Xing Semiconductor. Want to do big things?

- Zhou Ming joins hands with the Guangdong Basketball Association to produce another masterpiece! The

- ISE2023 Abbison's first exhibition in the new year has received frequent good news, and the immersiv

- Samsung Display and APS "work together" to create 3500ppi Micro OLED

- Zhouming Technology and Perfect World officially reached an educational ecological partnership!

- Longli Technology:Mini-LED has been shipped in batches to some in-vehicle customers, VR customers, e