Analysis of Mini/Micro LED driving technology

- author:

- 2024-06-04 15:06:41

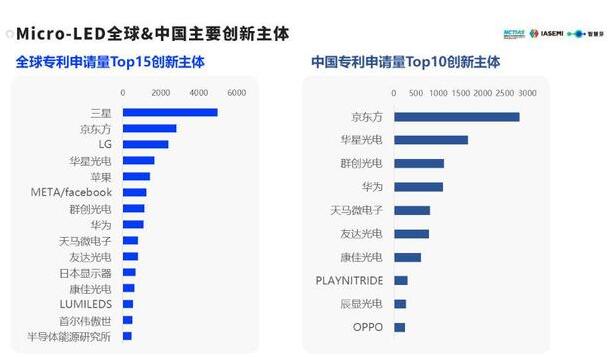

As the pixel density of LED display products becomes higher and higher, LED display application scenarios have been greatly expanded, and people have higher and higher requirements for image quality. In recent years, Mini/Micro LED has become a high-frequency term in the display industry. It can be said that Mini/Micro LED is the future of new high-definition displays. For this reason, major display manufacturers have increased investment in Mini/Micro LED technology research and deployed Mini/Micro LED display products.

The LED display industry has developed in China for more than 30 years, and indoor small-pitch products have also been developed for more than 10 years. What is the difference between Mini/Micro LEDs and previous small-pitch LED displays?

From an application perspective, the luminaries used in Mini/Micro LED display products are smaller than those used in conventional small-pitch LED display products, which means that the resolution per unit area of Mini/Micro LED display products is getting higher and higher. This has already affected the entire industry chain (such as driving solutions, substrates, transfer equipment, etc.) has had a profound impact, and has also promoted the development of the entire industry towards higher-level display technologies and products. It is bound to greatly expand LED display application scenarios, mainly in three major application areas:

The first application area: large size display applications

Micro LED has huge development potential and is gradually developing towards outdoor ultra-high-definition display applications, such as outdoor high-definition large screens, high-end exhibitions, high-end conferences and large size Micro LED TVs, which will greatly improve the quality of traditional large size LED displays;

The second largest application area: medium and size consumer applications

Micro LED will gradually replace LCD. It is the next generation of advanced display technology for oled and will be used in wearables, PC displays, high-end TVs, etc.;

The third largest application area: small size micro display applications

Such as AR, VR, MR, etc.

As Micro LED technology continues to mature, the LED display market has entered the era of large displays, and the capacity will gradually enter the trillion-level market with the development of Micro LED.

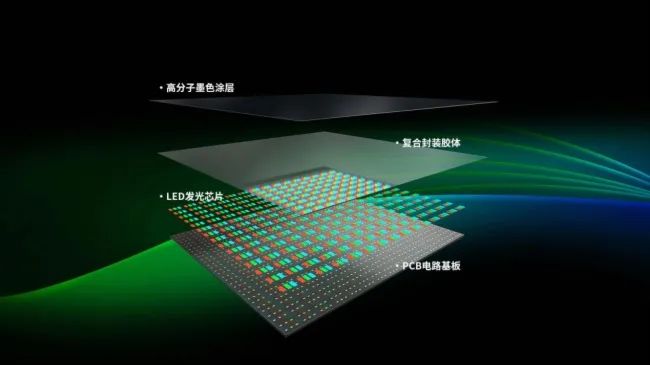

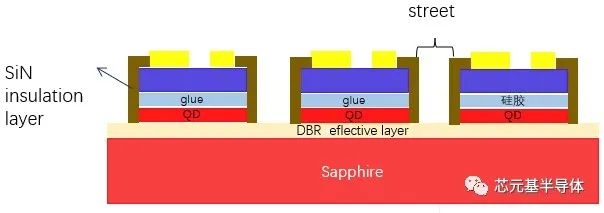

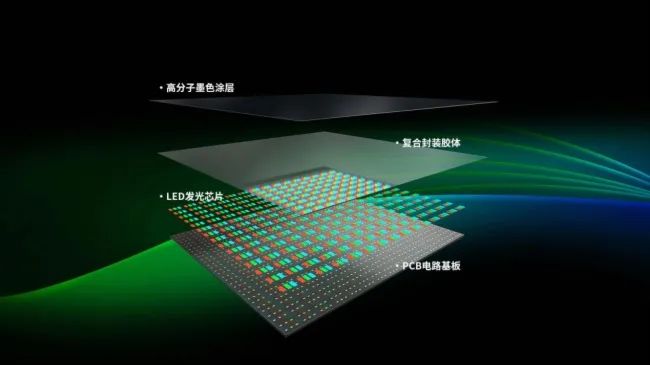

Although the market prospects are bright, the challenges in technology and products cannot be underestimated. First of all, Micro LED chips are very small. To realize the huge transfer of Micro LEDs and truly achieve mass production and commercial use, the upstream and downstream industries need to work together; Secondly, Micro LEDs currently mainly use PCB substrates for size display applications. In terms of large size display, the PCB substrate process technology is mature and can be mass produced and commercial. However, in terms of small and medium-sized size display applications, due to the significant increase in pixel density, the PCB's line width and warpage precision cannot meet the demand. The current development of glass substrates is in full swing, and samples are also displayed in the industry. However, it has not yet reached the stage where it can be mature for mass production and commercial use, mainly due to technology and cost constraints. In addition to the above two aspects, Micro LEDs need to be used on a large scale in small and medium-sized size displays, and the driving technology of Micro LEDs is also crucial. Conventional LED small-pitch driving solutions currently cannot meet the needs of Micro LEDs in higher resolution Small and medium-sized size applications. Currently, there are three main driving solutions used in Mini/Micro LED display products. Let us find out.

PM driven

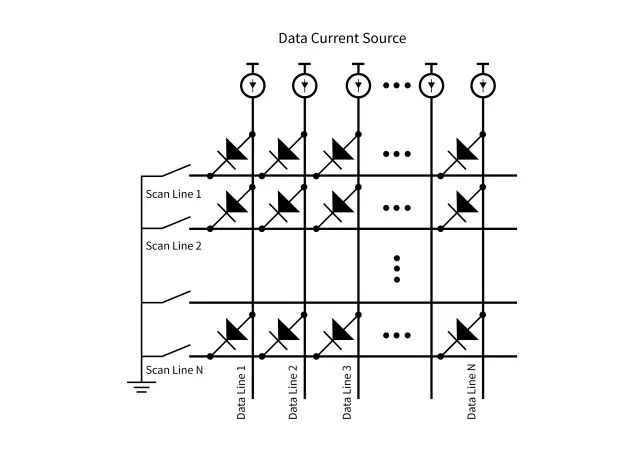

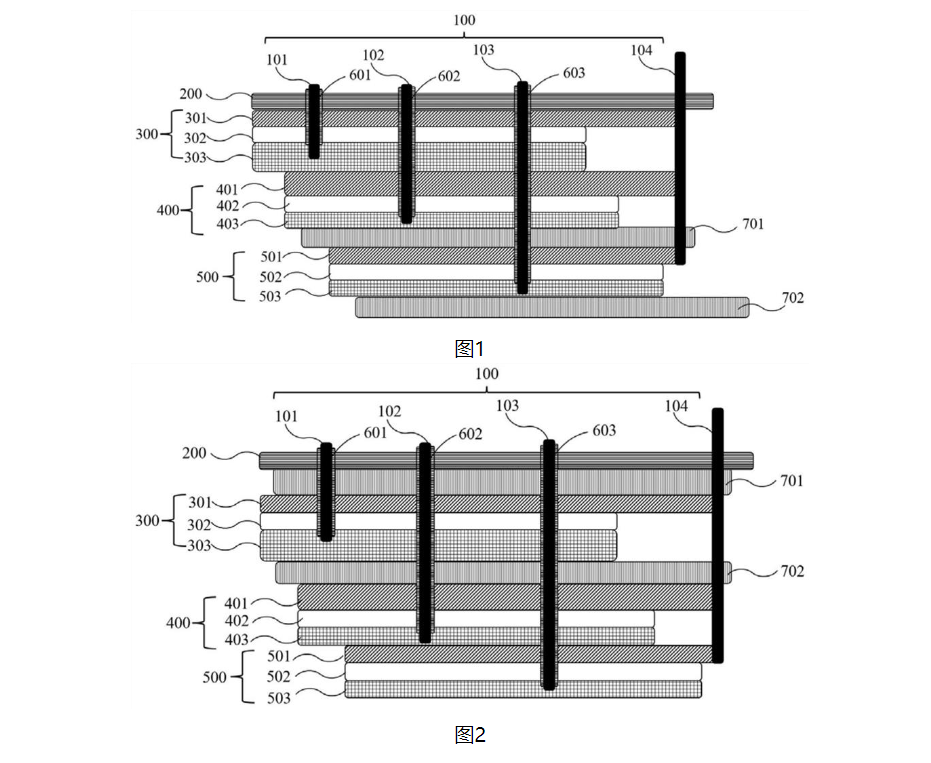

PM driving connects the P-electrode of each column of LEDs in the LED display array to the Data Current Source, and connects the cathode of each row of LEDs to the Scan Line. When a specific Yth column scan line and Xth row scan line are gated, the LEDs at their intersection (X, Y) are lit. The entire LED screen is scanned and lit at high speed point-by-point in this way, avoiding the persistence of vision of the human eye, and finally realizing the display screen, as shown in Figure 1.

This PM point-by-point scanning method is easier to implement, the PCB design and wiring are cumbersome, and the LEDs are lit up by cyclic high-speed scanning, and the lighting time is very short, so the brightness efficiency is low. Secondly, due to the design of a large number of scanning circuits, a large number of resistance-capacitance devices lead to obvious crosstalk between LED pixels and require high frequency of scanning signals. This actually poses challenges to the driving technology and cannot meet the application of Micro LEDs in small and size high-resolution screens.

Pixel density has been greatly improved in Mini/Micro LED display products compared with traditional small-pitch products, and the number of LED light-emitting devices has increased significantly. How can we control more LED light-emitting devices? At present, most of the solutions are large scanning and multi-channel highly integrated driver IC solutions, such as scanning methods from 16 scans, 32 scans, 64 scans or even 96 scans. If you just increase the number of scans, it may not be enough. It is difficult to place too many driver ICs on a limited substrate. At this time, more than 16-channel driver ICs were launched one after another to support the industry in making higher-definition LED display products.

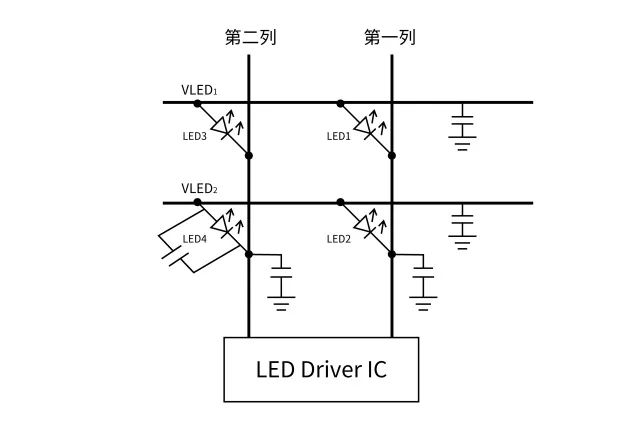

At present, PM high-scanning, multi-channel small-pitch LED driving solutions still cannot perfectly solve problems such as dark brightness, low-gray unevenness, and coupling under high contrast. These problems are mainly caused by the influence of parasitic capacitance. During the PCB design stage, Layout line adjustments can be made to reduce the size of parasitic capacitance. At the same time, the pixel spacing is getting smaller and smaller, the PCB lines are getting denser, and the impact of parasitic capacitance is more obvious. At present, it is very important to look at the driving scheme, and the PCB design cannot be ignored. See Figure 2.

AM driven

The AM driving method basically began to be studied in depth with the emergence of Micro LEDs. Because Micro LEDs can realize display products with higher PPI, PM drivers are difficult to meet the demand, and they are currently trying to apply it on COG. Compared with the PM drive image, the AM drive is like an EMU. Each carriage has its own power, which can achieve a higher brightness utilization rate of the Micro LED. The PM drive is like a green leather train, with only the front of the train. Power is provided. In the end, the front of the train is used to transmit power to subsequent carriages. It is like PM's point-by-point scanning lighting. The LED is lit up in a high-speed cycle, so the PM drive's screen brightness is less efficient. Due to high-speed scanning, the display image is also unstable. This does not match the use of small and size Micro LEDs in the consumer market. Overall, AM mainly has the following advantages: it can better realize Micro LED display products with higher PPI, achieve higher brightness, lower power consumption, and With more uniform brightness, higher contrast and more stable image display, it is foreseeable that AM drivers will become a better driving solution for mass production and commercialization of Micro LEDs in small and medium-sized size in the future.

"semi-active drive

Semi-active driving uses a single transistor as the driving circuit of Micro-LED pixels, which can avoid crosstalk between pixels. This driving solution is actually an intermediate solution between PM and AM, which can bring into full play the advantages of PM and AM. It is currently less used in LED displays, but with the continuous upstream and downstream research on the commercial application of Micro LEDs in the industry, semi-active drivers may also be useful in the future.

The above is the thinking on the current Mini/Micro LED display applications, as well as the three commonly used driving solutions and their advantages and disadvantages. The industry will choose applications based on large, medium and small size applications, based on technology, mass production and price maturity. However, based on the rapid development of Mini/Micro LED display technology and products, higher definition, higher image quality, and lower energy consumption are the development trend of ultra-high definition. We believe that AM drivers may become the main driving technology direction for Mini/Micro LED displays in small and medium size displays in the future.

TAG:

Guess you want to see it

Popular information

-

Involving key patents involving Mini LED, Zhaoyuan Optoelectronics, Xinruida, etc. disclosed...

-

POB and COB: Who will dominate the future of Mini LED applications?

-

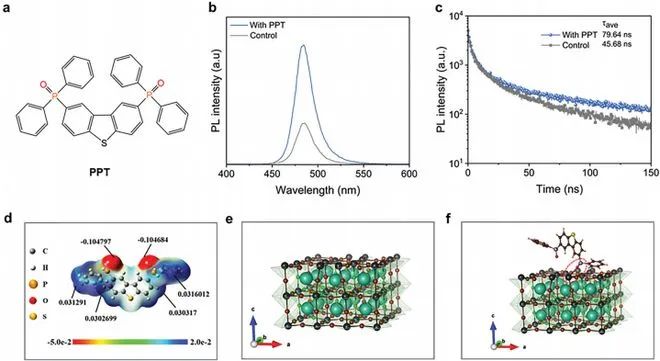

Soochow University makes new progress in white perovskite LED research

-

This company has obtained invention patents related to MINI LED

-

Core-based high-efficiency pure red light quantum dot chip has been achieved, and QD-Mini LED is abo

-

Analysis of Mini/Micro LED driving technology

-

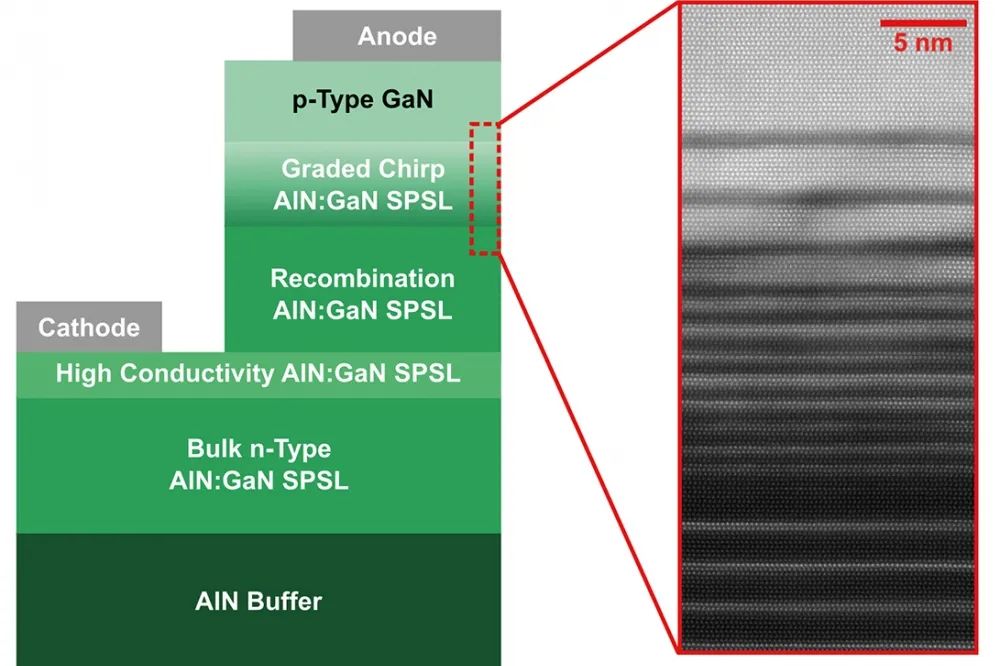

Australia company Silanna UV achieves mass production of ultraviolet LEDs

-

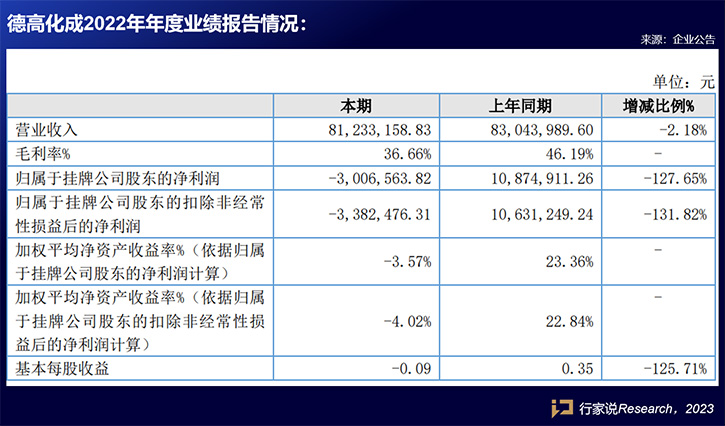

JCDecaux Chemical Corporation: The development of new Mini display-related products is progressing,

-

Milestone breakthrough? UVC-LED new lens appears

-

Korea Photonics Technology Research Institute says the efficiency of Micro LED technology has been g

the charts

- JCDecaux Chemical Corporation: The development of new Mini display-related products is progressing,

- The total investment exceeds 26 billion yuan! This year's Mini/Micro LED is something to watch!

- Involving key patents involving Mini LED, Zhaoyuan Optoelectronics, Xinruida, etc. disclosed...

- Division 5184! TCL launches Mini LED TV with peak brightness of 5000nit

- Mini/Micro LED equipment manufacturer Keyun Laser has completed Series B financing of over RMB 100 m

- Lenovo releases a new 34-inch hairtail display equipped with Mini LED backlight technology

- POB and COB: Who will dominate the future of Mini LED applications?

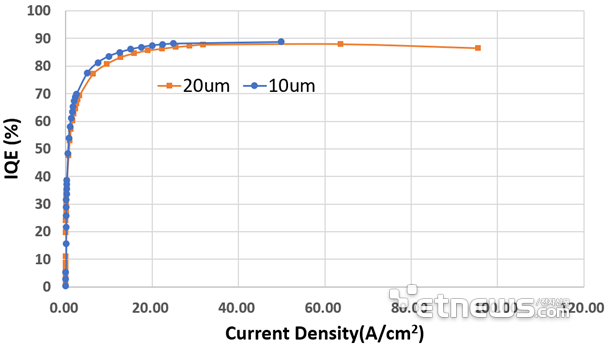

- The internal quantum efficiency has been increased to 70%, and this team has made a breakthrough in

- High-precision optical processing, this team used MINI-LED technology as a breakthrough point

- Analysis of Mini/Micro LED driving technology