Korea Photonics Technology Research Institute says the efficiency of Micro LED technology has been g

- author:

- 2024-06-04 15:27:04

Recently, Micro LED has accelerated its financing. Since October alone, four companies have announced financing progress. Driven by capital and enterprises, Micro LED has also ushered in some new progress in technology.

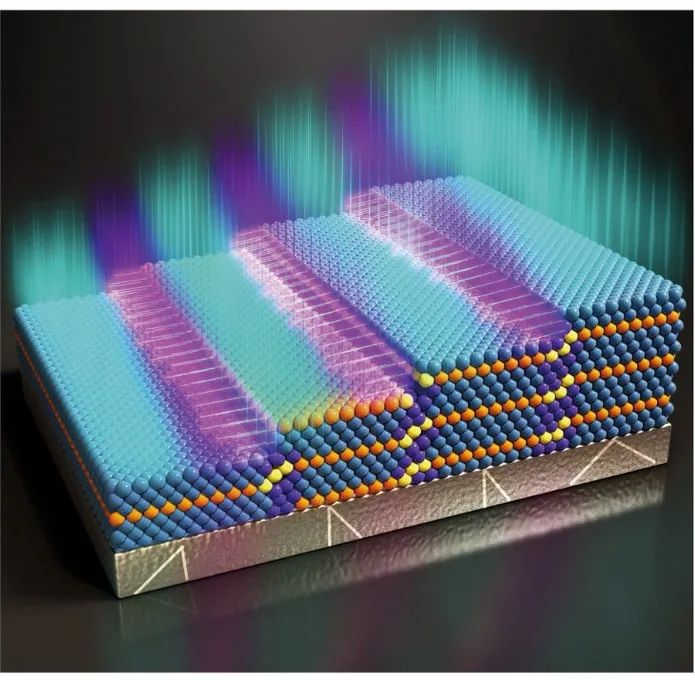

Korea Photonics Technology Research Institute makes new progress in Micro LED luminous efficiency

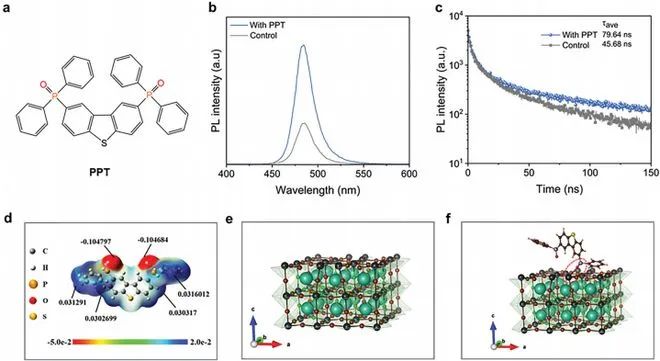

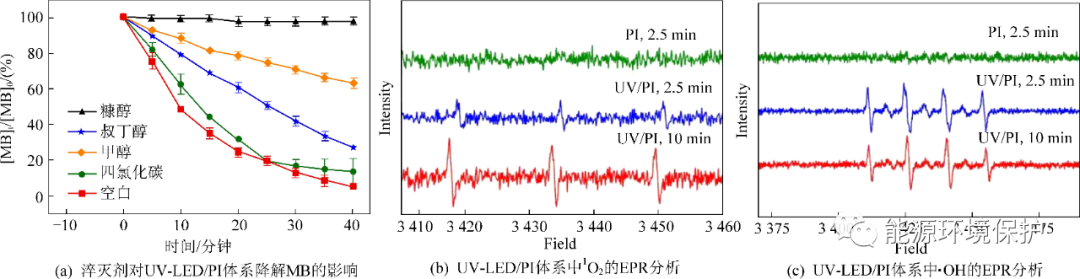

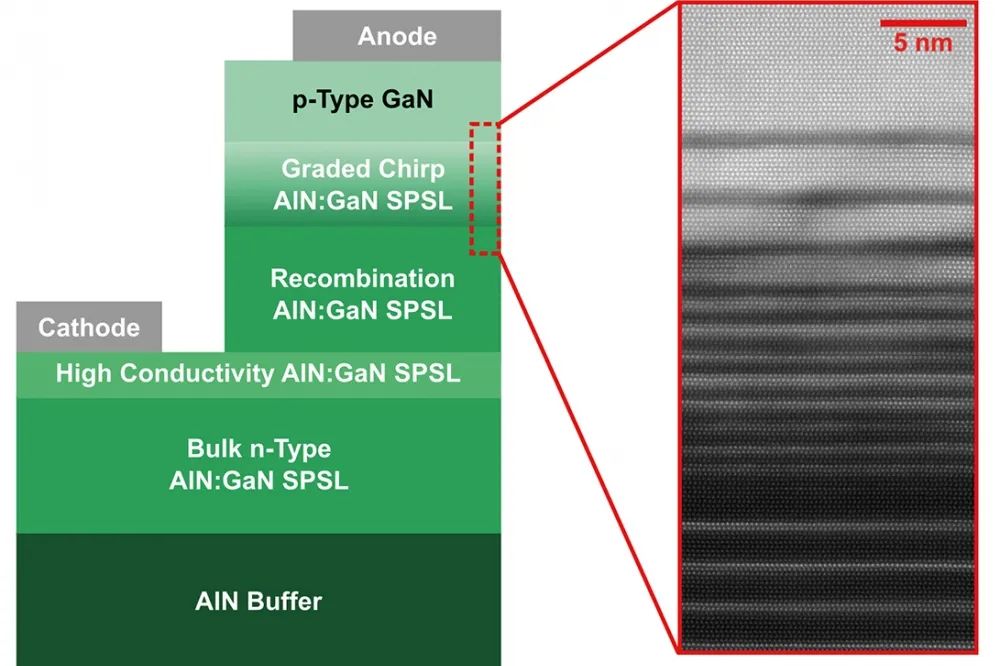

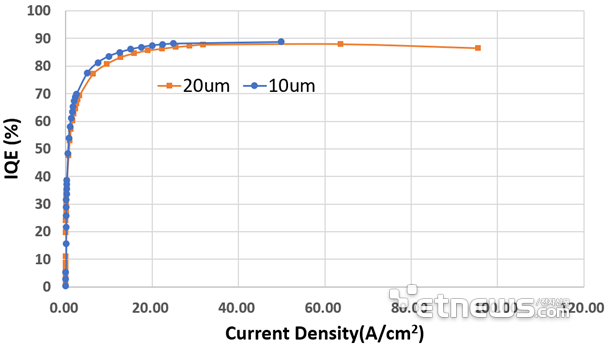

Recently, according to South Korean media reports, the Korea Institute of Photonics Technology (KOPTI) announced that it has successfully developed a high-efficiency and fine Micro LED. The internal quantum efficiency of Micro LEDs can be maintained within 90%, and is not affected by chip size and different injection current densities.

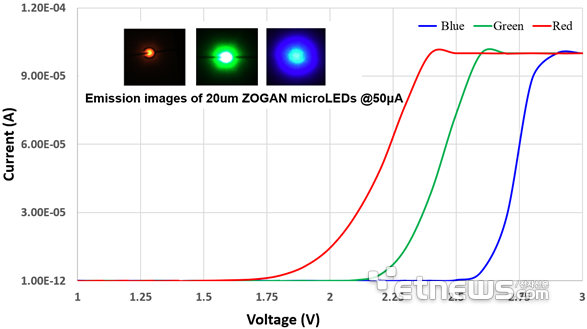

Current-voltage curve and emission image of 20 m Micro LED (Photo source: KOPTI)

This Micro LED was jointly developed and built by Dr. Jong hyup Baek's team from the Optical Semiconductor Display Research Department, the ZOGAN Semi team led by Dr. Woong ryeol Ryu, and Professor Jong in Shim from the Department of Nano-Optoelectronics of Hanyang University. The product solves the problem of rapid decline in luminous efficiency of Micro LEDs due to shrinking chip size and increasing injection current.

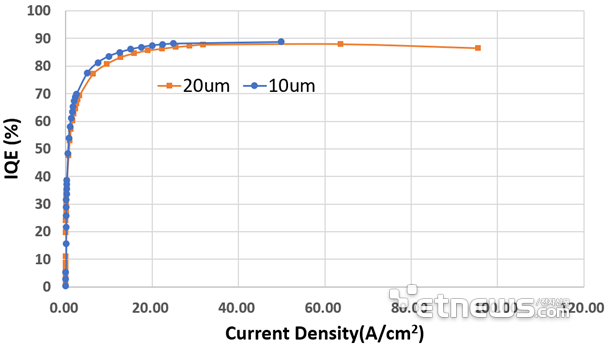

It is reported that Micro LEDs with a size below 20 m not only decrease in luminous efficiency, but also increase the non-luminous recombination loss of Micro LEDs significantly within the low current range (0.01A/cm²~1A/cm²) required to drive the display panel. At present, the industry can alleviate the above problems to a certain extent by introducing passivation processes on the side of the chip, but it cannot be fundamentally solved.

Changes in internal quantum efficiency (IQE) of 20 m and 10 m blue Micro LEDs according to current density

KOPTI introduced that the research team used the new structure to reduce the stress in the epitaxial layer, improve the luminous efficiency, and suppress the physical stress changes of Micro LEDs under any external electric field or structure. Therefore, even if the Micro LED size is reduced, the new structure can still significantly reduce surface non-luminescent recombination loss and maintain high luminescent efficiency without requiring a passivation process.

At present, the team has successfully verified the application of high-efficiency and fine Micro LEDs in blue light, gallium nitride green and red light devices. It is expected to produce full-color gallium nitride Micro LED displays through this technology in the future.

Taiwan Industrial Research Institute develops two-in-one rapid detection technology for Micro LED display modules

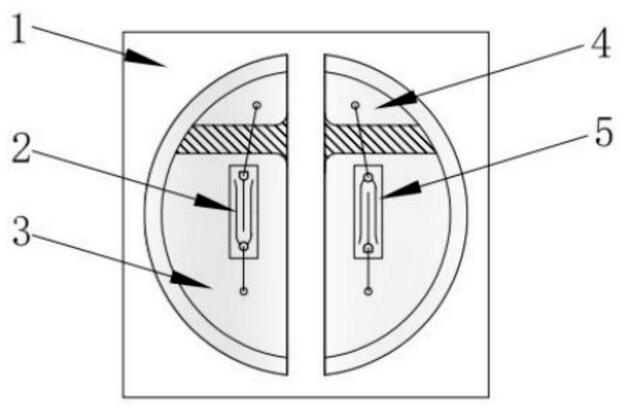

According to the Taiwan Economic Daily, recently, the Taiwan Industrial Research Institute has focused on the two core points of color correction and optical testing, and successfully developed a high-accuracy two-in-one Micro LED display module rapid detection technology that can simultaneously detect color and light source angle.

Lin Zengyao, executive director of the Measurement Technology Development Center of the Taiwan Industrial Research Institute, said that because the technology is too forward-looking and there are no certain specifications on the market, Micro LEDs must be customized and developed in accordance with the unique needs of the brand factory. Therefore, there is no precedent for testing or repairing. Following, the R & D team of the Taiwan Industrial Research Institute first started with color uniformity testing that the industry urgently needs to solve.

Because the Micro LED size is very small, the camera pixels of the lens of traditional display measurement equipment cannot meet the testing needs. The R & D team of the Taiwan Industrial Technology Research Institute uses repeated exposure color correction technology to achieve color balance of the Micro LED panel through repeated exposure, and analyzes color uniformity through optical correction technology to achieve accurate measurement purposes.

At present, the R & D team of the Industrial Technology Research Institute in Taiwan installs multi-angle light-receiving lenses on existing optical measuring machines. By gathering light sources from different angles at one time, and then using original software analysis technology, the light sources are presented on the same interface at the same time. In addition to achieving fixed-point measurement and significantly reducing the detection time by 50%, it has also successfully broken through the traditional 100-degree light source angle detection and expanded it to about 120 degrees.

It is worth noting that the Taiwan Industrial Research Institute, with the support of the Technology Department, has successfully developed a high-accuracy two-in-one rapid detection technology for Micro LED display modules, which uses a two-station method to quickly analyze the color uniformity and angular optical rotation of micro light sources. Characteristics, provides customers with customized testing of various new products, and improves the measurement efficiency by 50% compared with traditional equipment. We hope that through technical testing, we can help the industry break through mass production difficulties and enter the new world of next generation display.

TAG:

Guess you want to see it

Popular information

-

Involving key patents involving Mini LED, Zhaoyuan Optoelectronics, Xinruida, etc. disclosed...

-

The latest research on UV LED solves 2 problems

-

Analysis of Mini/Micro LED driving technology

-

Australia company Silanna UV achieves mass production of ultraviolet LEDs

-

Division 5184! TCL launches Mini LED TV with peak brightness of 5000nit

-

POB and COB: Who will dominate the future of Mini LED applications?

-

MIT researchers demonstrate perovskite nanoscale LED arrays

-

Korea Photonics Technology Research Institute says the efficiency of Micro LED technology has been g

-

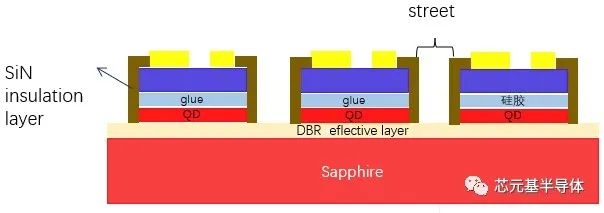

Core-based high-efficiency pure red light quantum dot chip has been achieved, and QD-Mini LED is abo

-

High-precision optical processing, this team used MINI-LED technology as a breakthrough point

the charts

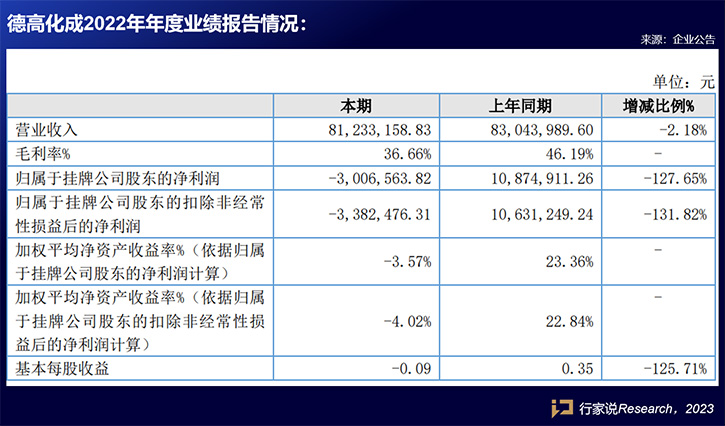

- JCDecaux Chemical Corporation: The development of new Mini display-related products is progressing,

- The total investment exceeds 26 billion yuan! This year's Mini/Micro LED is something to watch!

- Involving key patents involving Mini LED, Zhaoyuan Optoelectronics, Xinruida, etc. disclosed...

- Division 5184! TCL launches Mini LED TV with peak brightness of 5000nit

- Mini/Micro LED equipment manufacturer Keyun Laser has completed Series B financing of over RMB 100 m

- Lenovo releases a new 34-inch hairtail display equipped with Mini LED backlight technology

- POB and COB: Who will dominate the future of Mini LED applications?

- The internal quantum efficiency has been increased to 70%, and this team has made a breakthrough in

- High-precision optical processing, this team used MINI-LED technology as a breakthrough point

- Analysis of Mini/Micro LED driving technology