Milestone breakthrough? UVC-LED new lens appears

- author:

- 2024-06-04 16:19:06

Recently, Japanese industrial rubber manufacturer Asahi Rubber launched a new ultraviolet optical material (DUV280). The material hasa transmittance of more than 90% to 280nm UV-C light and little performance loss after 15,000 hours of e=70mW irradiation.

It is worth noting that according to Asahi Rubber, this materialuses silicone, which has certain advantages in achieving complex shapes and precisions. Two standard lenses are currently available: one is AL-10M-DUV280, which has a distribution angle of ~10, which is mainly compatible with 3535 package LEDs; the other is AL-20M-DUV280, which has a distribution angle of ~20, which is mainly compatible with 6868 package LEDs. Applications for DUV280 optical devices include sterilization and skin phototherapy.

It is understood that Asahi Rubber was established in May 1970 and was listed on the Tokyo Stock Exchange Standard Market in September 1998. In May of this year, a colored silicone lens was released, focusing on adding materials compatible with deep ultraviolet (UV-C, DUV), making the product excellent heat resistance and weather resistance, and can be used in high temperature and ultraviolet environments.

As the industry knows, the shorter the wavelength of ultraviolet light emitted by UV LED chips, the higher the absorption coefficient of organic materials. For example, the absorption edge of ordinary polystyrene and acrylic is about 385nm, and the transmittance at 275nm is equivalent to zero. Therefore, in the field of UVC-LED, it is particularly important to choose the right lens (also known as optical window) material for packaging.

At present,inorganic materials with high transmittance are mainly used in the UVC-LED band, mainly quartz glass and sapphire, with transmittance ranging from 90% to 93%. If the coating process is added to quartz glass, the transmittance can be increased by 4% ~7%, reaching 96% ~ 99%. But at the same time, costs will more than double.

However, we can find that the new ultraviolet optical material released by Asahi Rubber is mainly used in the packaging end, in spherical form, but the material used belongs to silicone materials, which is different from the current mainstream supply of inorganic materials.

At present, the mainstream UVC-LED packaging method has no semi-inorganic packaging. It mainly uses organic silicon materials with inorganic materials such as quartz glass. The purpose is to reduce the light fading problems caused by organic materials and the failure problems caused by humid heat stress. If the transmission rate of silica gel materials can reach 90%. If some subsequent properties can be extended to semi-inorganic packaging routes, there may be opportunities to bring new imagination.

Zheng Yuanzhi, general manager of Yuanrong Jiesheng,believes that the aging of silica gel has not yet been solved and will still crack for a long time. The industry has been trying to break through. In addition, amorphous fluororesin can resist ultraviolet, but its unit price is higher and the process is relatively complicated. The transmittance of silica gel is not bad, but its weather resistance needs to be strengthened. If Asahi Rubber really achieves a transmittance of more than 90% of UV-C light at 280nm and hasΦ almost no performance loss after 15,000 hours of e=70mW irradiation, it will be a milestone breakthrough for UVC-LED packaging.

TAG:

Guess you want to see it

Popular information

-

The total investment exceeds 26 billion yuan! This year's Mini/Micro LED is something to watch!

-

Australia company Silanna UV achieves mass production of ultraviolet LEDs

-

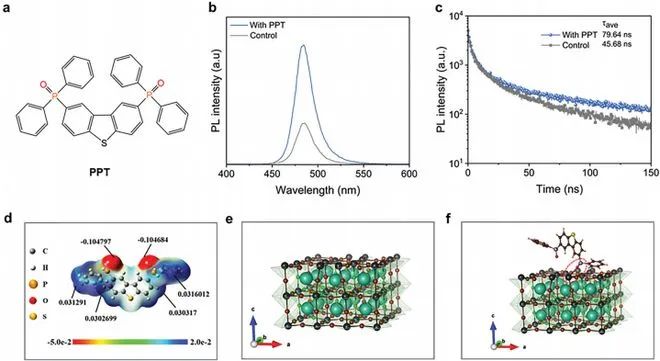

The internal quantum efficiency has been increased to 70%, and this team has made a breakthrough in

-

Milestone breakthrough? UVC-LED new lens appears

-

MIT researchers demonstrate perovskite nanoscale LED arrays

-

Korea Photonics Technology Research Institute says the efficiency of Micro LED technology has been g

-

Core-based high-efficiency pure red light quantum dot chip has been achieved, and QD-Mini LED is abo

-

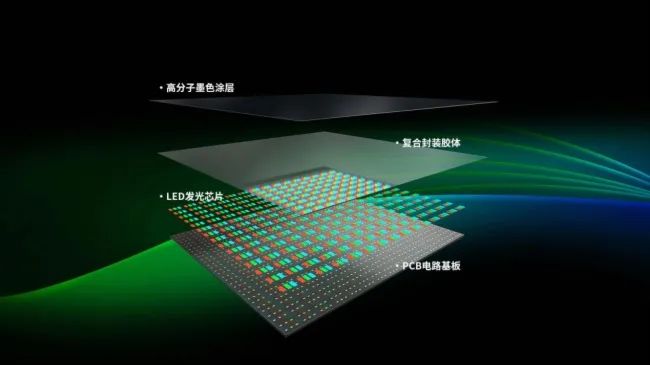

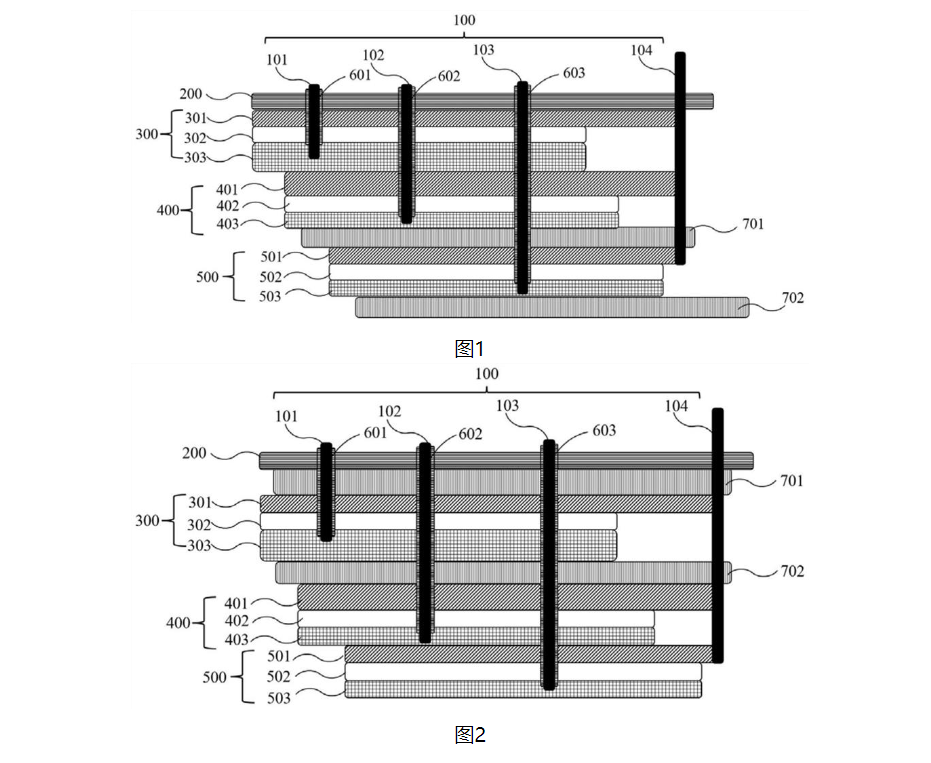

LED screen production technology: Micro-LED vs. Mini LED

-

Division 5184! TCL launches Mini LED TV with peak brightness of 5000nit

-

The latest research on UV LED solves 2 problems

the charts

- JCDecaux Chemical Corporation: The development of new Mini display-related products is progressing,

- The total investment exceeds 26 billion yuan! This year's Mini/Micro LED is something to watch!

- Involving key patents involving Mini LED, Zhaoyuan Optoelectronics, Xinruida, etc. disclosed...

- Division 5184! TCL launches Mini LED TV with peak brightness of 5000nit

- Mini/Micro LED equipment manufacturer Keyun Laser has completed Series B financing of over RMB 100 m

- Lenovo releases a new 34-inch hairtail display equipped with Mini LED backlight technology

- POB and COB: Who will dominate the future of Mini LED applications?

- The internal quantum efficiency has been increased to 70%, and this team has made a breakthrough in

- High-precision optical processing, this team used MINI-LED technology as a breakthrough point

- Analysis of Mini/Micro LED driving technology