COB flushing, rear packaging attracts attention

- author:

- 2024-05-27 10:28:45

Especially in terms of production capacity, the COB camp has begun to release production capacity. Many companies have successively received news of pilot trials of COB products, production lines being put into production and mass production. Another leading company's monthly production capacity has reached 16000 square meters (calculated based on P1.25 point spacing products).

In terms of products and markets, COB has strengthened its penetration in the commercial display and home markets. At major exhibitions, many companies exhibited COB all-in-one machines and TVs.

From production capacity to application, high reliability and high display quality products are still the key, which requires the support of production lines and equipment.

In the early days of COB's development, the industry's focus was more on front-end technology and die bonding. As the mass production problem is gradually solved, how to improve the back-end packaging process to make the quality of COB products more reliable has become a new focus of the industry.

01

COB rear packaging process helps improve product quality

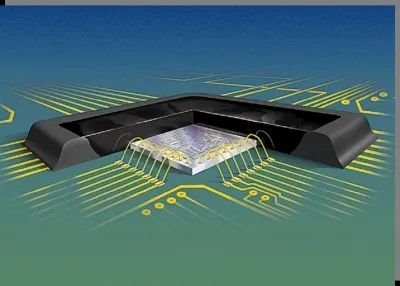

From the perspective of COB process, if COB products want to achieve high reliability and high display quality, the COB module rear packaging process is an important link. Why?

First of all, high-reliability products mean fewer defects and high yield. The inspection and repair equipment for the COB rear packaging process can accurately find and repair defective points in the previous process to ensure product quality.

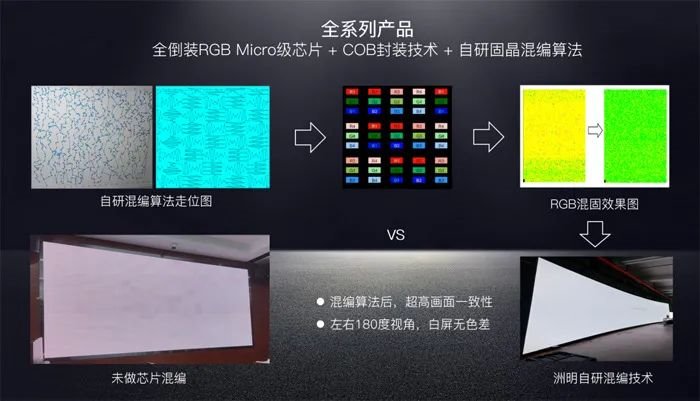

Secondly, the quality of the display effect is determined by optical performance and ink consistency technology. At present, equipment such as jet printing, primer coating, and ink sorting in the post-packaging process can reduce the color difference of the PCB background color, improve the contrast of the COB unit board, and Achieve ink classification, effectively achieving consistent display effects of finished products.

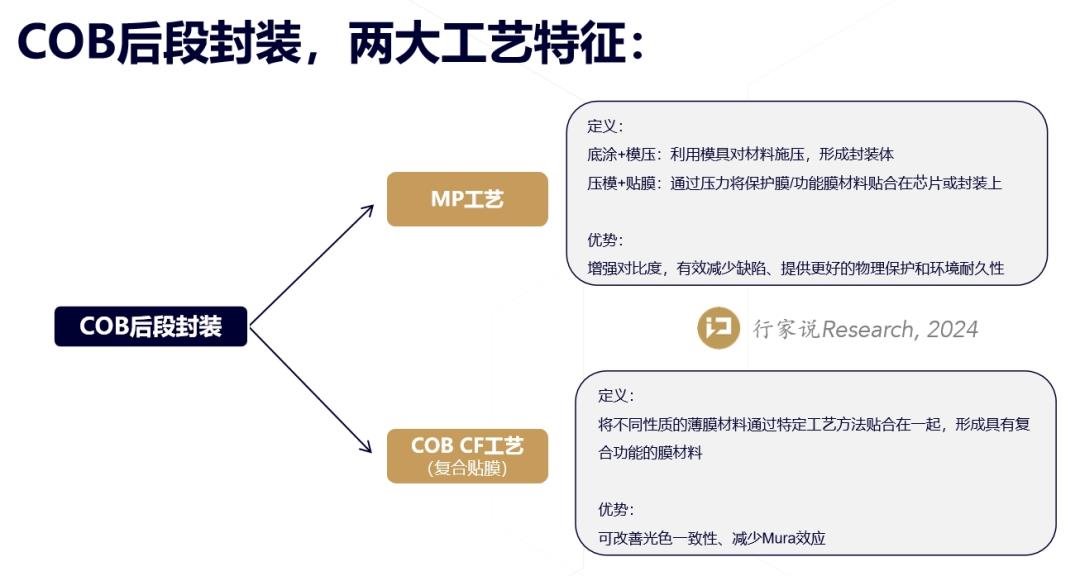

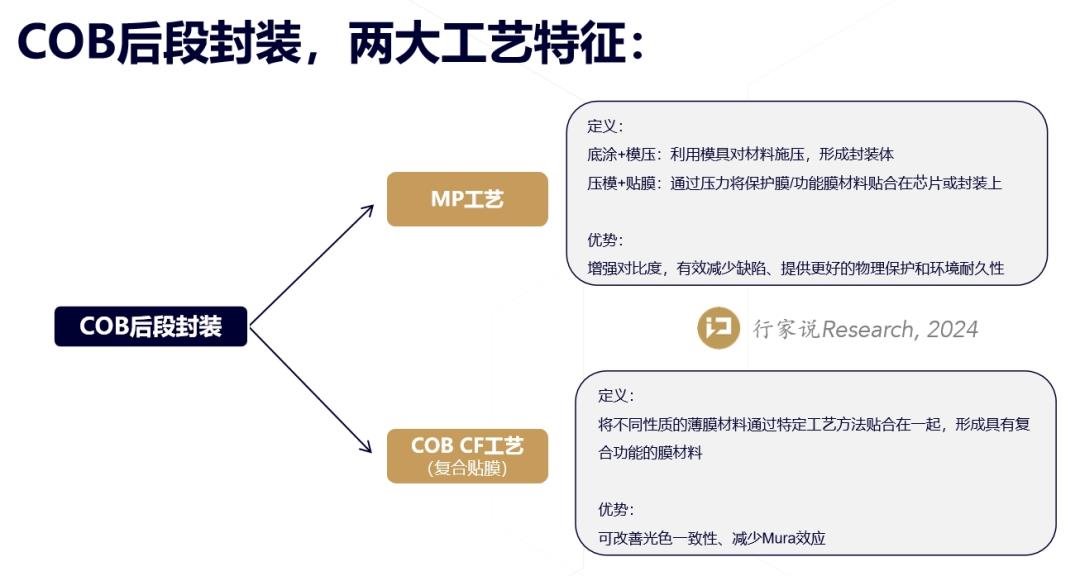

Currently, based on different equipment and solutions, COB rear packaging mainly presents two major processes, one is MP process (molding process plan), and the other is COB CF (composite film) process. The advantages of the two major processes are as follows:

Overall, different packaging processes have their own advantages and application scenarios. Based on this, equipment manufacturers have laid out suitable packaging processes based on their own characteristics, production capabilities and market positioning.

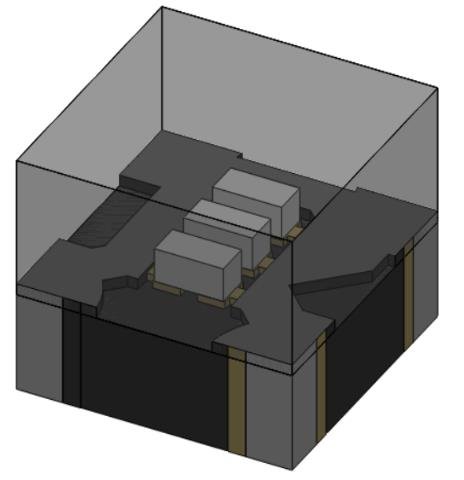

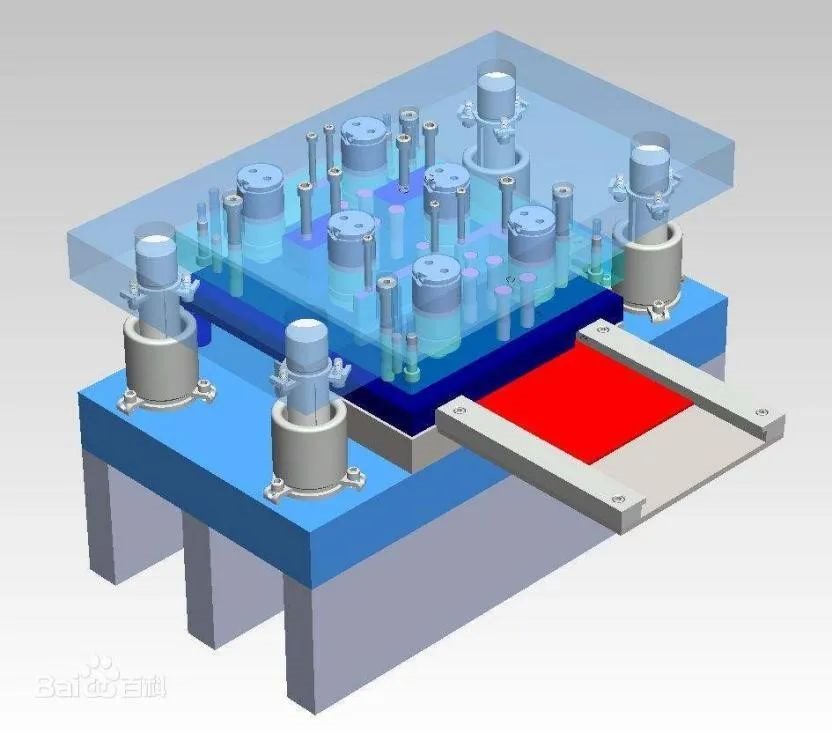

Taking Zhongzhi Bonda, which owns both COB MP process and COB CF process, as an example, the company has established a complete COB rear packaging line, which can provide complete process and equipment solutions for the industry.

Source: Provided by the enterprise

From the perspective of enterprises, the parallel of dual processes will help CIIC Bonda remain competitive in the current market and be more flexible in subsequent development, which is reflected in the following three aspects:

(1) Meet the needs of more customers and improve market competitiveness.

Dual process routes can meet more diverse market needs; secondly, mastering multiple packaging routes will also help companies maintain their advantages in technological innovation and attract high-end customers.

(2) Achieve improvement in efficiency and production efficiency and improve market competitiveness.

Under the dual-process route, equipment factories can integrate different process plans to achieve resource sharing and optimize configuration, and can also quickly adjust production lines according to order needs to achieve the goal of reducing costs and improving efficiency.

(3) Risks are dispersed and development is more flexible.

In the face of market changes, companies with multiple processes can adjust their development strategies more quickly and seize the development trend of the industry.

From an industry perspective, dual-process parallel equipment factories can provide customized solutions for industry pain points such as yield improvement, ink consistency, and heat dissipation performance optimization, and solve some key problems in the industry; at the same time, companies with multiple processes are more aware of technological changes in the industry, and are more capable of participating in the formulation of industry standards and promoting industry development.

02

Launched MLED three-in-one intelligent laser repair equipment/laser window opening machine

The repair issue of COB has always been the focus of attention in the industry. In addition to the above production line processes, it is understood that Zhongzhi Bonda's Mini/Micro LED three-in-one intelligent laser repair equipment/laser window opening machine can also solve the repair problems of COB and other technical routes.

During the repair process of COB packages, the industry faces three major problems: one is the issue of rework efficiency, the other is the issue of rework cost, and the third is the issue of positioning/operation accuracy that needs to be improved. In response to these problems, Zhongzhi Bonda's Mini/Micro LED three-in-one intelligent laser repair equipment provides specific solutions:

Repair efficiency issues

The single-point repair efficiency of Zhongzhi Bonda equipment only takes 15 seconds, which can be about doubled compared with the 25-35 seconds repair time of most equipment in the industry.

In addition, it also has two working methods: online fully automatic and offline fully automatic. Both methods can automatically complete a series of production or repair tasks. The three platforms of crystal removal/crystal bonding/welding operate independently to achieve improved efficiency; At the same time, this kind of working method can also reduce manual intervention, reduce the possibility of product rework, and achieve cost reduction.

Repair cost issues

Zhongzhi Bonda equipment has complete and powerful software functions; it can realize full-closed-loop production process control of pre-testing and post-review, and achieve real-time monitoring of the repair point status, the amount of tin dots, and all data-based statistical analysis of the fixed crystal offset., early warning and correction, and SPC one-click statistical data output to ensure the reliability and consistency of repaired products, reduce the possibility of repair, thereby realizing cost control.

Problems with positioning accuracy and operation accuracy

For repair equipment, parameters such as vision system resolution, laser control accuracy, XYZ axis movement accuracy, and placement/spot printing accuracy will all affect product accuracy.

In response to the above technologies, Zhongzhi Bonda's Mini/Micro LED three-in-one intelligent laser repair equipment continues to make efforts in chip placement accuracy, welding and de-soldering accuracy through five major technical applications, in order to achieve high-precision repair effects, improve product quality and production efficiency. The specific technology is shown in the following figure:

In addition to focusing on repair problems such as efficiency, cost, and accuracy, Zhongzhi Bonda's Mini/Micro LED three-in-one smart laser repair equipment also has a wide range of repairability.

It is reported that this device can be used in fields such as Mini LED display, Mini LED backlight, and Micro LED display, and can also adapt to the repair needs of Mini/Micro LED products with various chip size and substrates, such as in terms of substrates, the materials it can process include PCB, FPC, FR4, aluminum substrate, glass substrate, etc.

Overall, Zhongzhi Bonda's Mini/Micro LED three-in-one intelligent laser repair equipment provides an automated, accurate and widely applicable repair solution by integrating multiple laser repair technologies, effectively responding to COB packaging The problems faced in the repair process meet the market demand for high-reliability COB products. In the future, as LED displays continue to develop towards smaller spacing and higher density, this device will also stimulate greater market prospects.

03

Experts say Display summary

As COB technology becomes increasingly mature and the market expands, the focus of the industry is gradually shifting from front-end processes to back-end packaging processes.

As a solution provider for COB back-stage packaging equipment, Zhongzhi Bonda is actively deploying COB technology to help solve problems such as reliability, display performance improvement and repair of COB products through two major packaging processes and new equipment.

TAG:

Guess you want to see it

Popular information

-

Analyze outdoor COB display screens from Asian Games events

-

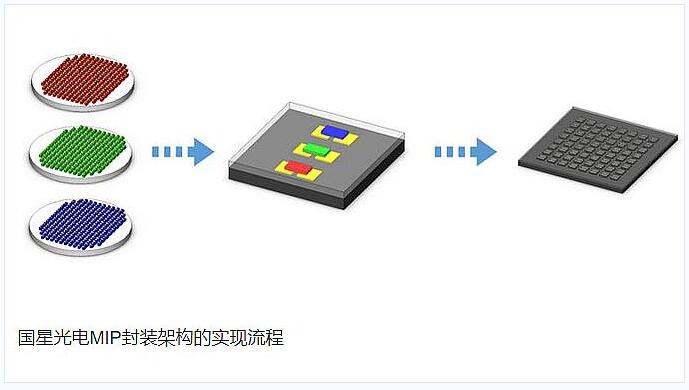

Which of the two technologies is the mainstream route, MIP or COB?

-

Detailed explanation of COB packaging process: the key to improving product quality

-

COB flushing, rear packaging attracts attention

-

Technical analysis of COB, IMD, mini, micro LED market

-

Three main development directions of COB packaging technology

-

An article clearly understands what GOB is in led display protection technology, what are the advant

-

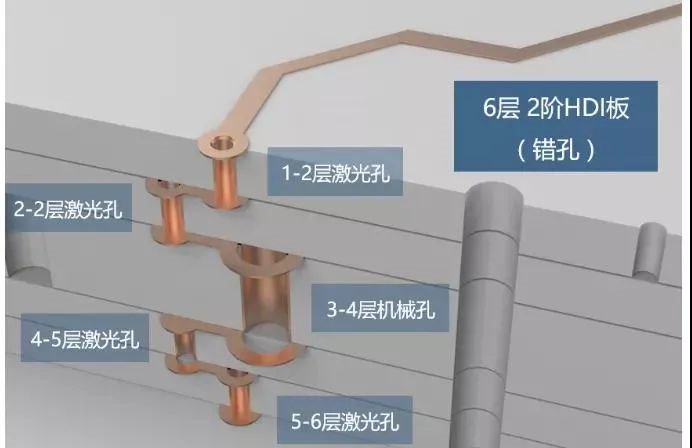

Analysis of COB mid-to-high-end PCB design process through 3D pictures

-

The difference between COB package and traditional SMD package

-

COB technology helps display enter the era of p0.XXmm HD

the charts

- Technical analysis of COB, IMD, mini, micro LED market

- Expand another 1100 COB production lines, and the MLED display card displays the "Big Era"

- COB flushing, rear packaging attracts attention

- What is the difference between GOM,COB, and msd packages?

- Which of the two technologies is the mainstream route, MIP or COB?

- LED dynamic multiplexing pixel technology for COB and COG panels

- Detailed explanation of COB packaging process: the key to improving product quality

- Analyze outdoor COB display screens from Asian Games events

- Exploring the secret of LED screen production: Process comparison between COB technology and SMD tec

- What are the LED chip packaging materials used to package COBs?