How to view the reasons for poor consistency of COB ink?

- author:

- 2024-05-27 11:46:47

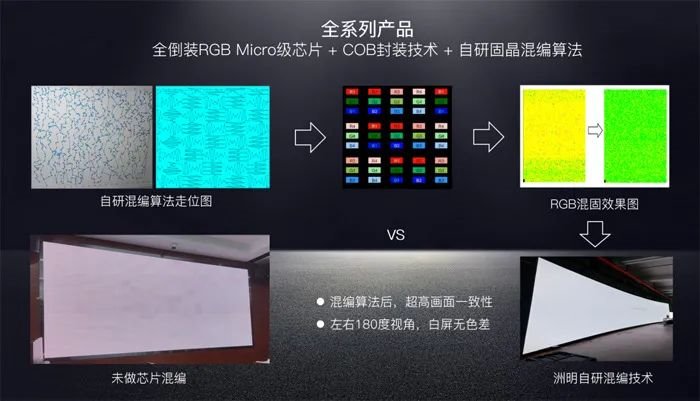

There are a series of problems in the actual application process of COB displays. For example, due to the thickness tolerance of PCB substrates in the same batch or different batches, and the sealing material flows at different times and different batches. There are also differences in flow rates, which makes it extremely easy to cause obvious modularity of the display, which is manifested in inconsistent colors in different areas of the same board. The colors of different panels in the same box are also different, and related problems such as reflection of the panel may even occur.

In order to solve the modularity problem of spliced COB displays, the following surface treatment technologies are commonly used to achieve consistent display effects.

PCB surface treatment

For COB packaged displays using PCB substrates, the unit boards will also show color differences due to differences in the background color of the substrates.

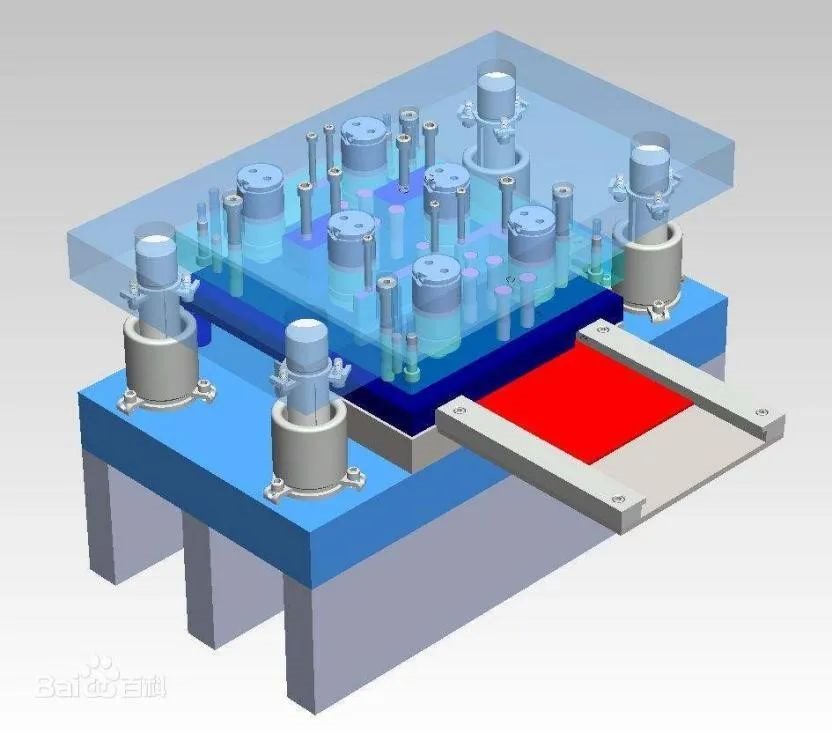

In order to improve the contrast of COB unit boards, black PP can be used during the production process of PCB substrates or black solder resist can be used to cover non-functional areas. It is also a practical method to spray ink in the chip spacing areas after die bonding. Taking Lehman's existing PCB board with built-up chips as an example, the black proportion before the die bonding wire is about 45%, and after inkjet comparison, the black proportion increases to 75%. Depending on different chips, a space 100% larger than the chip is reserved for die bonding. After processing, the proportion of black in the entire screen (hereinafter referred to as the black proportion) is up to 80%(the proportion of chips requiring wire bonding is even smaller), much less than 99%. High-speed precision spraying technology can achieve precise positioning. Ink can be sprayed even in tiny gaps between chips. Spray printing requires no screen printing, shortening the working process, ink recycling, no loss, and can be installed with a UV curing light source. Long life, energy conservation and environmental protection.

Cell board/box surface treatment technology

Ion sputtering equipment is used to spray a uniform black coating on the surface of the COB unit board to achieve an integrated black effect; a black glue film can also be made and closely adhered to the surface of the unit board of the box, which can greatly improve the contrast. Display screen image contrast refers to the measurement of different brightness levels between the brightest white and the darkest black in the light and dark areas in an image, that is, the gray contrast of an image. The larger the difference range means the greater the contrast, and the smaller the difference range means the smaller the contrast. Spray the blackest material on the surface of the unit board to minimize the darkest black value and achieve a contrast ratio of 10000:1.

Correction consistency technique

In COB small dot pitch packaged displays, the dot spacing becomes smaller and smaller, and the actual spacing between lamps becomes smaller and smaller, which leads to mutual crosstalk between pixels and blurred image overlap. In addition, the COB packaging process causes the three-color light to reflect inside the gel, causing interference again, which affects the accuracy of collecting the brightness of lamp beads.

Before correction

corrected

Comparison of COB module before and after correction

There is a significant difference between low-gray performance and high-gray performance, and the problem of inconsistency in low-gray segments is prominent.

Display effect of the screen at different gray levels

The low gray scale effect is related to circuit design, chip selection, and hardware control; the low gray coefficient is easily affected by the above conditions and the color realization is inaccurate, resulting in poor display effect.

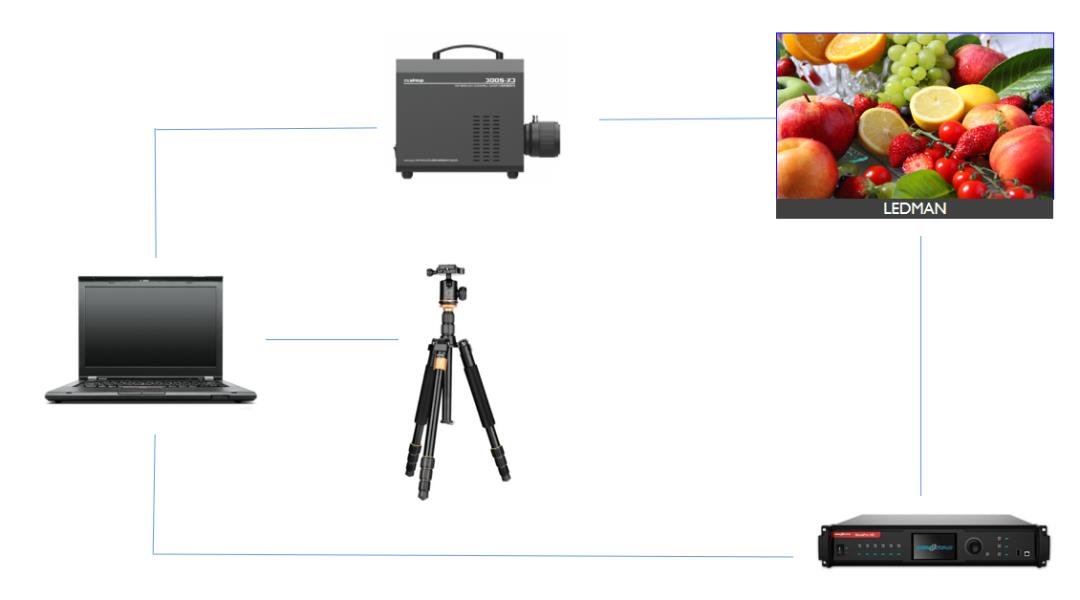

Display screen correction system

The correction effect can be improved through the following aspects.

1

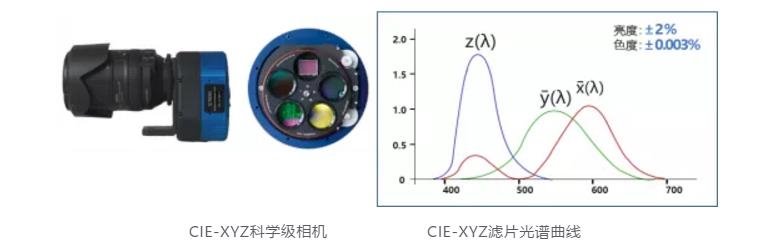

Adopt scientific-grade cameras to improve measurement accuracy

A CIE-XYZ filter that conforms to the perception characteristics of the human eye is adopted to reflect the true perception of the human eye.

CIE-XYZ Scientific Camera

Due to cost considerations, conventional cameras usually use simple Bayer filters, but Bayer filters are spectrally unstable and have the problem of uneven transition of burrs, which can lead to serious spectral measurement errors. Through years of filter design innovation and continuous iteration, the calibration camera adopts CIE-XYZ filter technology, and the iteration is a CIE-XYZ scientific level camera. The high-specification camera introduces a filter calibration algorithm for LED measurement design, and selects multiple groups of rotating wheels, multiple measurements are made to ensure the accuracy of the measurement and obtain measurement data that conforms to the characteristics of the human eye, making the correction closer to the picture effect perceived by the human eye.

2

Improve the correction process and add light elimination processing

The collected image is processed twice, its own brightness data is restored, and the correction data under the real brightness is counted again. Improving the uniformity of the screen body and making the display effect more delicate is the new mixed light elimination technology for COB display.

3

Full gray scale correction technology improves gray scale performance accuracy.

Gray scale data is collected through the light gun CA-410, and then correction coefficients are calculated through the gray scale correction tool to compensate each gray scale to improve the nonlinear response. Finally, the gray scale display step problem is optimized on the receiving card through hardware coding.

In terms of COB display effect, traditional PCB surface treatment technology, unit board and box surface treatment technology are used to improve display consistency. Lehman adopts a display correction system and full gray scale correction technology to improve gray scale performance accuracy. The contrast effect before and after full gray scale correction shows that compared with before correction, the problems of pits, color blocks, and color cast in the corrected display screen are significantly improved, and the uniformity and picture delicacy are greatly improved.

There are a series of problems in the actual application process of COB displays. For example, due to the thickness tolerance of PCB substrates in the same batch or different batches, and the sealing material flows at different times and different batches. There are also differences in flow rates, which makes it extremely easy to cause obvious modularity of the display, which is manifested in inconsistent colors in different areas of the same board. The colors of different panels in the same box are also different, and related problems such as reflection of the panel may even occur. If these problems cannot be properly solved, they will seriously affect the display effect and experience of COB displays, which in turn restrict their further promotion and application in the market.

TAG:

Guess you want to see it

Popular information

-

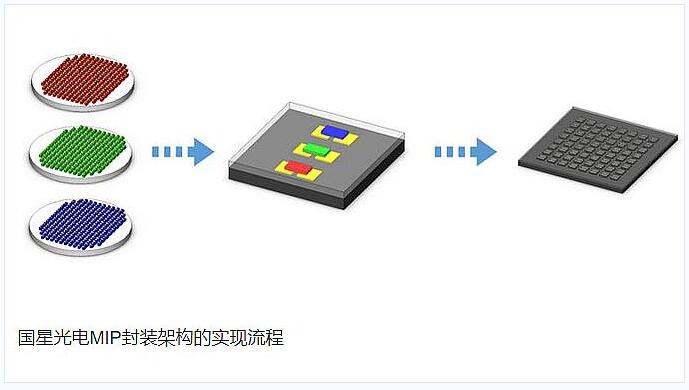

Which of the two technologies is the mainstream route, MIP or COB?

-

Analyze outdoor COB display screens from Asian Games events

-

How to view the reasons for poor consistency of COB ink?

-

Technical analysis of COB, IMD, mini, micro LED market

-

COB packaging: advantages and challenges coexist

-

What are the LED chip packaging materials used to package COBs?

-

COB technology helps display enter the era of p0.XXmm HD

-

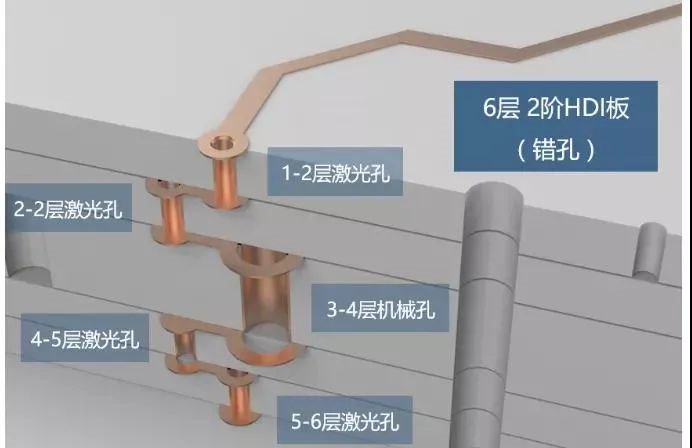

Analysis of COB mid-to-high-end PCB design process through 3D pictures

-

An article clearly understands what GOB is in led display protection technology, what are the advant

-

What is the difference between GOB and COB displays?

the charts

- Technical analysis of COB, IMD, mini, micro LED market

- Expand another 1100 COB production lines, and the MLED display card displays the "Big Era"

- COB flushing, rear packaging attracts attention

- What is the difference between GOM,COB, and msd packages?

- Which of the two technologies is the mainstream route, MIP or COB?

- LED dynamic multiplexing pixel technology for COB and COG panels

- Detailed explanation of COB packaging process: the key to improving product quality

- Analyze outdoor COB display screens from Asian Games events

- Exploring the secret of LED screen production: Process comparison between COB technology and SMD tec

- What are the LED chip packaging materials used to package COBs?