99.88% yield! Seoul National University Micro LED Mass Transfer New Breakthrough

- author:

- 2024-06-04 16:20:42

On July 12, Kwon Sung-hoon, a professor at the Department of Electrical and Information Engineering at Seoul National University, disclosed the technology of stably mass production of Micro LEDs using Fluid Self-assembly in the international academic journal Nature. Jin Changshun, a professor at the Laboratory of Organic Electronics and Nanooptics at Seoul National University, also participated in the research.

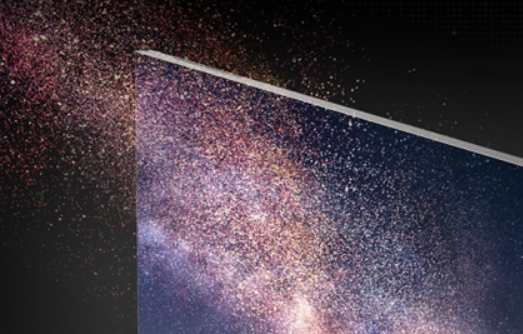

Micro LEDs have higher performance and energy efficiency than oleds, which are mainly used in the display industry. Micro LEDs can achieve clearer colors than OLEDs with less energy. In addition, each component of a Micro LED is smaller than an OLED, so you can put more components than an OLED on the same size screen. Therefore, displays made with Micro LEDs have much better picture quality than OLED displays.

At the same time, Micro LEDs will not have the fatal shortcoming of OLEDs-the Burn-in phenomenon. The branding phenomenon means that the life of the components that make up the display screen is about to end, and residual images will be left on the screen. OLEDs are made of organic substances with weak light and heat. The longer the use time, the worse the brightness and color gamut, and branding is prone to occur. Unlike OLEDs, Micro LEDs are made of inorganic materials with good durability, and branding rarely occurs.

The problem is that Micro LEDs are difficult to mass produce. Like the previous way of making display elements, using a robotic arm to assemble parts one by one on the substrate, the number of Micro LED parts is too small, resulting in a decline in yield.

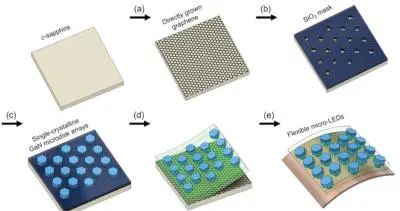

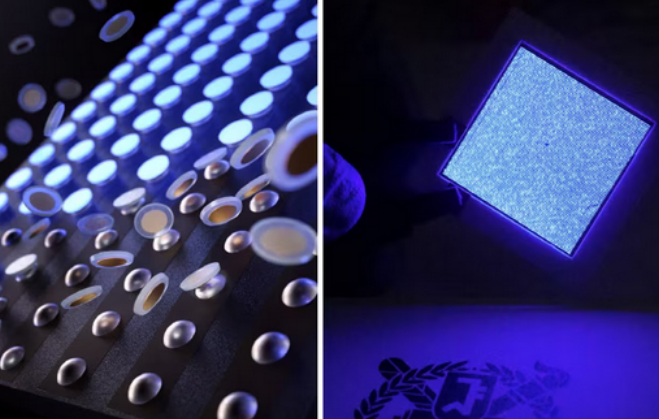

In this regard, the research team decided to apply the fluid magnetic assembly method to the Micro LED production process. The Micro LED accessories and the substrate used in assembling the accessories were put into a barrel and shaken together with a specially made solution, and the accessories would find themselves. Position, successfully developed the technology completed by Micro LED. The research team confirmed that when using this technology to make Micro LEDs, the yield rate was 99.88%.

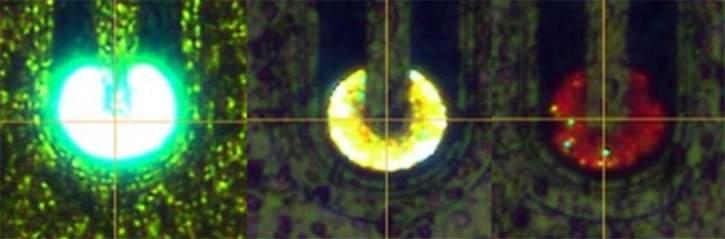

The research team also made a prototype to confirm the performance of the Micro LEDs they made. A blue light-emitting panel was made using 20,000 Micro LEDs made with fluid self-assembly technology, and it was confirmed that there were no problems in operation. The Micro LED is 45 microns long (microns, 1 micron is one millionth of a meter) and 5 microns thick, which is 16 times thinner than a hair thickness of about 80 microns.

Professor Quan has previously achieved various research results by self-assembly of fluids. In 2008, the ultra-small Eiffel Tower, Greek temples, computer keyboards, etc. were made by making tiny grooves on the substrate floor, pouring liquid containing ultra-small parts with a size of dozens to hundreds of hectares on it, and pouring the parts into self-assembly. The research team explained that the Micro LED manufacturing technology manufactured this time is also on its extension line.

Professor Quan said: The yield recorded in this study is a very epoch-making figure in the field of Micro LED mass production. In the future, through more research, we will strive to achieve the ideal yield rate of 99.9999999%. quot; Professor Quan's research team has conducted joint research with LG Electronics in the past five years in order to produce this technology.

The paper containing the research results was published in the international academic journal Nature.

TAG:

Guess you want to see it

Popular information

-

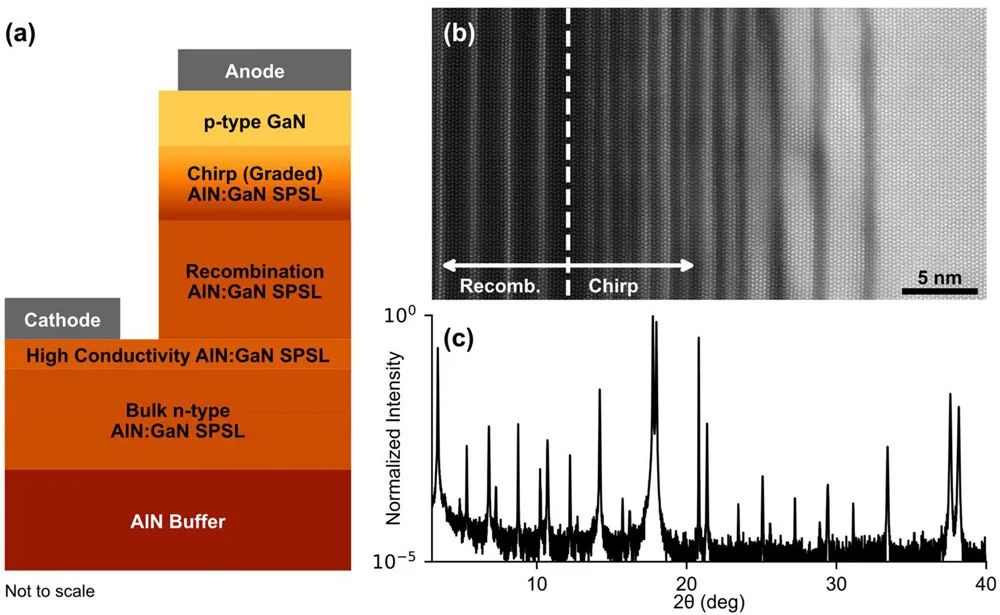

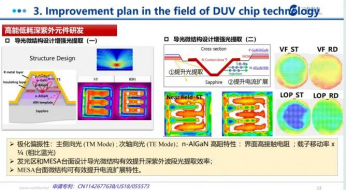

It can improve the light extraction rate of far-ultraviolet LEDs, and Silanna UV technology has beco

-

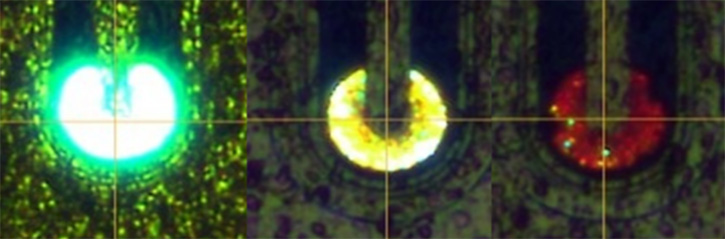

Red MicroLED R &D competition accelerates: Material innovation can solve the problem of luminous eff

-

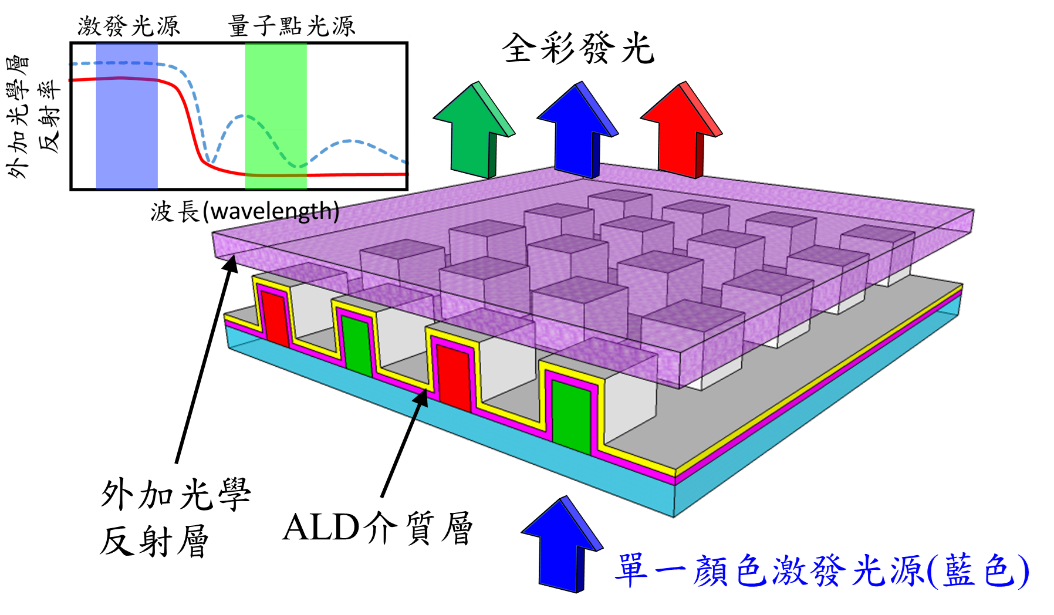

National Taiwan University teamed up with Yang Ming Jiao Tong University to make new progress in the

-

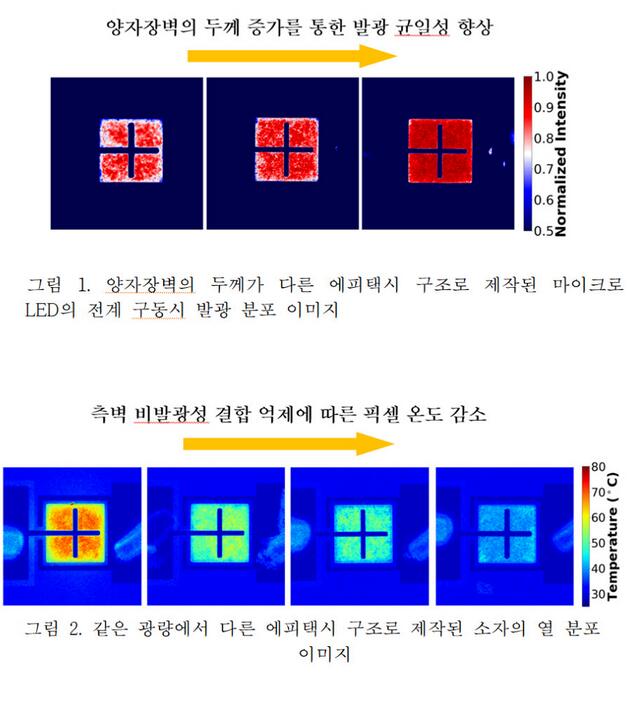

Micro LED heating capacity reduced by 40%! This study is supported by Samsung

-

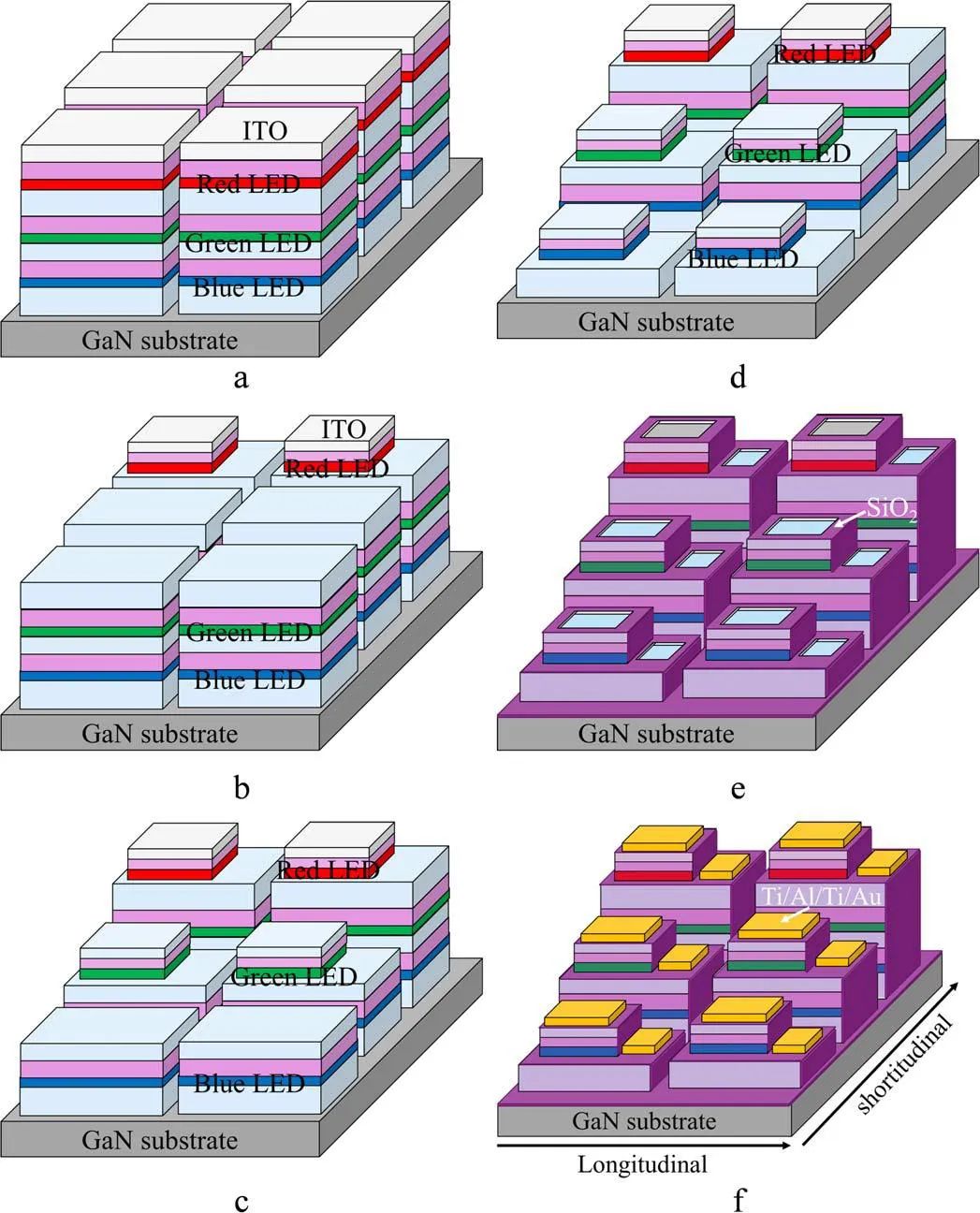

Researchers from the two universities collaborated to develop laminated full-color Micro LEDs

-

Micro LED achieves breakthrough results again

-

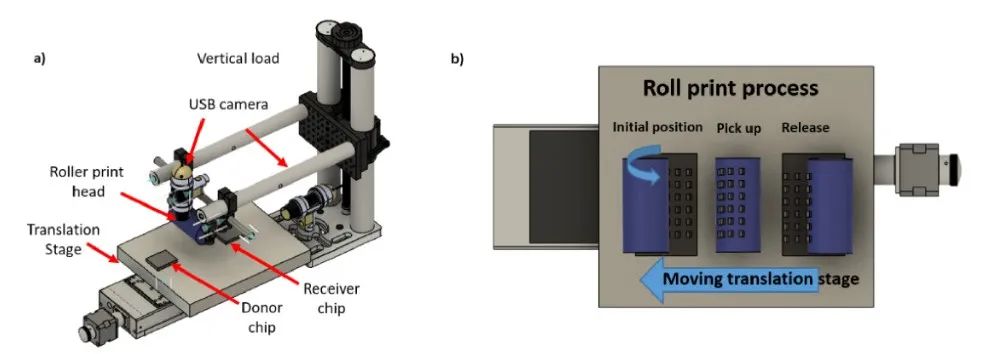

With more than 75000 grains per time, British researchers developed Micro LED continuous roller tran

-

The latest research progress of ultraviolet LEDs comes from Sanan Optoelectronics

-

Stanford University develops flexible, stretchable IC and successfully drives Micro LED screens

-

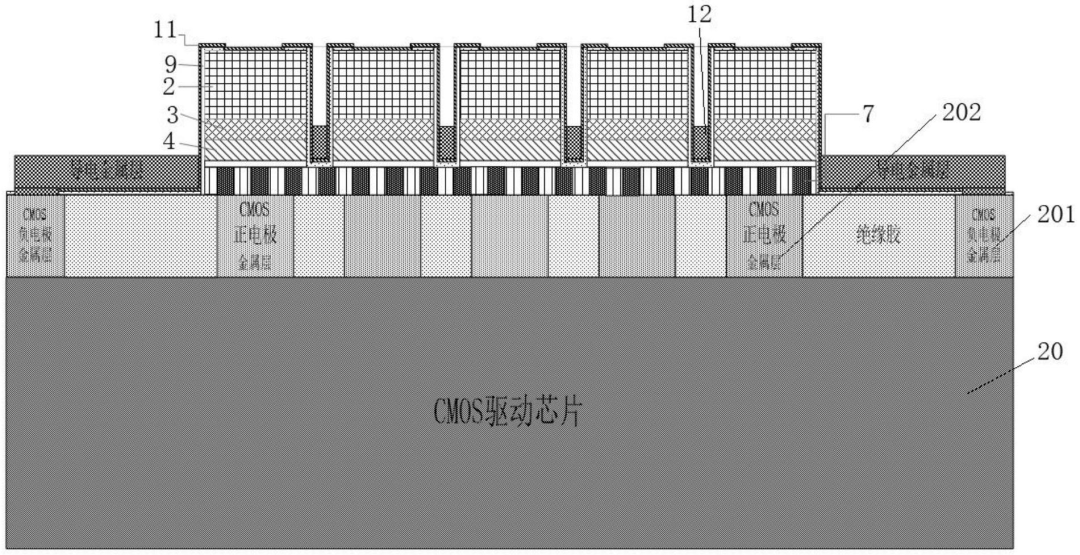

The latest progress of Micro LED chips! 4 units disclosed

the charts

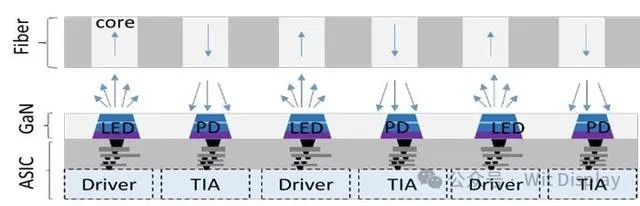

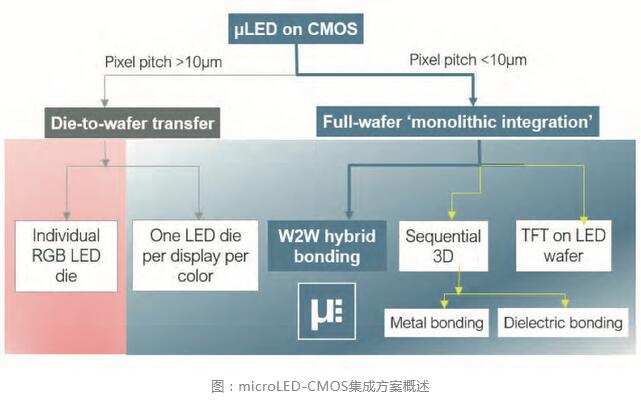

- The best solution for AR glasses? Integrating Micro LEDs with advanced CMOS

- Red MicroLED R &D competition accelerates: Material innovation can solve the problem of luminous eff

- Micro LED heating capacity reduced by 40%! This study is supported by Samsung

- Zhejiang University's micro-level Micro-LED array achievements were selected into the top ten scient

- Red MicroLED R &D competition accelerates: Material innovation can solve the problem of luminous eff

- Analysis of huge transfer technology: How to break through the Micro LED display process problems?

- technology| Interpretation of MicroLED Technology in Mico Display Principles

- Micro LED achieves breakthrough results again

- Micro 0.4 released globally, opening a new era in the LED industry

- A team from Xiamen University designs artificial nanostructures that enhance deep ultraviolet light